- Joined

- Mar 8, 2008

- Messages

- 26,145

Shape and friablilty play a bigger role then people give credit.

Here is SiC cutting a ceramic knife.

Shouldn't be possible if it worked on hardness alone

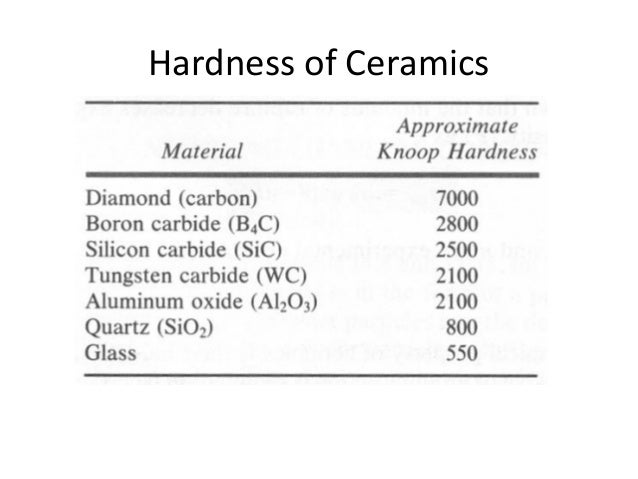

Ah, but silicon carbide is actually harder than zirconium dioxide. Like, roughly twice as hard. Aluminum oxide is harder than zirconium dioxide, too, though by a much smaller margin.

That being said, some degree of wear does occur to the harder of the two surfaces, which is why abrasive grains blunt through use in the first place.