Willie71

Warren J. Krywko

- Joined

- Feb 23, 2013

- Messages

- 12,214

Warren, do you think that at 64, the 8670 is essentially "untempered?"

I might send in an as quenched sample.

Warren, do you think that at 64, the 8670 is essentially "untempered?"

That sounds fancier than I can handle, unless it is a downloadable excel file.It would be nice if we could set up an interactive feature, so the chart can be ranked based on steel, hardness, or toughness, so comparisons would be easier. I’m not sure if this forum can do that.

That sounds fancier than I can handle, unless it is a downloadable excel file.

Developmental stainless steel.What is "New Steel" identity?

Developmental stainless steel.

5% Unobtainium?Developmental stainless steel.

5% is way too much. 2.5%5% Unobtainium?

Sure anyone can heat treat samples to send to me. We even have volunteers for machining the specimens to the correct specification.Great thread, looking forward to see more results.

I'm about to have a custom chopper done in 6150, any chances to test it?

Have used Ztuff, Zwear, INFI, 3V, Delta3V....so I will test it on the "battlefield", but those scientific data are a bit harder to get at home

Thanks guys for your work anyway!

Are you asking if there is a way to ensure that the Rockwell test is accurate at high hardness? Or if there is a way to make the steel tougher at high hardness?From my perspective its looking like some of those samples are losing a lot of toughness in a very narrow range of hardness. I know some may be do to a high temper vs low temper but others might be falling off real fast. I have heard that once you get above 60 Rc that each point begins to have a larger affect do to resisting a larger % of volume of the indenter. Is there a way of increasing test sensitivity in that range? Is that effect as big as its been made out to be?

He means testing at every rockwell point. For example, 8670 scored 51.0 at rc 59.7 and only 6.1 at 63.9 rc, but we don't know how it would do at the hardnesses in between.

I'm saying that how I have heard it explained is that Rc testing uses a cone shaped indenter and measures the depth of penetration. Because of this once you get to the higher points there is a larger jump in hardness. For example: the jump in hardness from 62 to 63 Rc is significantly greater than 52 to 53. If this is the case and the toughness levels for a given steel are falling off quickly then maybe there is a reason to target a hardness of 62.7 or some other off the dot hardness. And the reason for this very precise target number being that the difference between the 50s and the 60s is a 2 to 1 or a 3 to 1 increase in hardness.Are you asking if there is a way to ensure that the Rockwell test is accurate at high hardness? Or if there is a way to make the steel tougher at high hardness?

Thanks for taking the time to explain. I shall update my understanding that has been hard won by prowling forums.Never a break from tough questions around here.

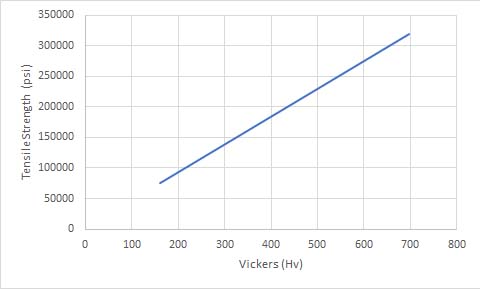

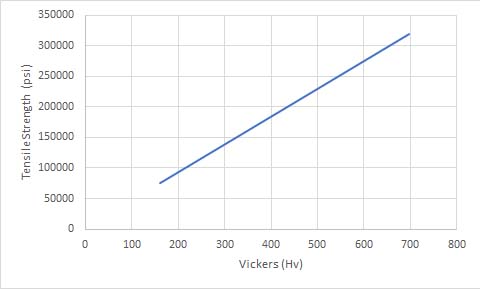

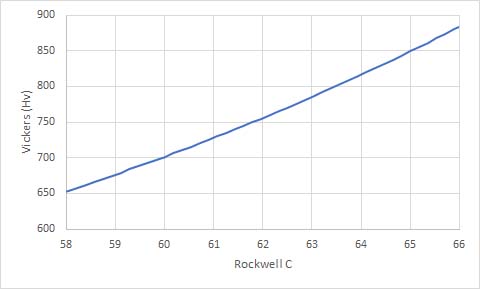

Some hardness tests, like Vickers are basically linear with tensile strength:

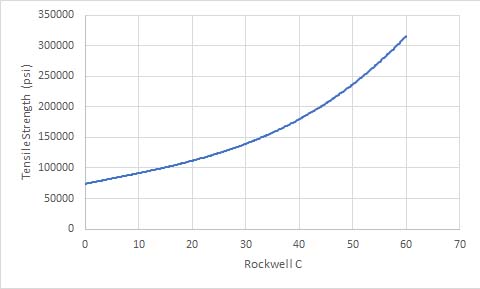

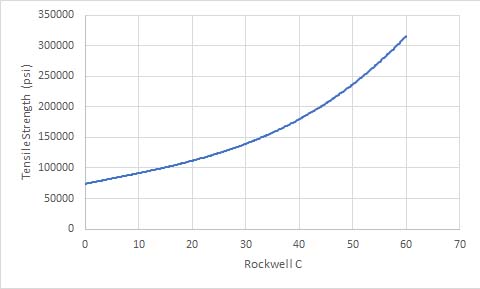

Rockwell C hardness, however, is not:

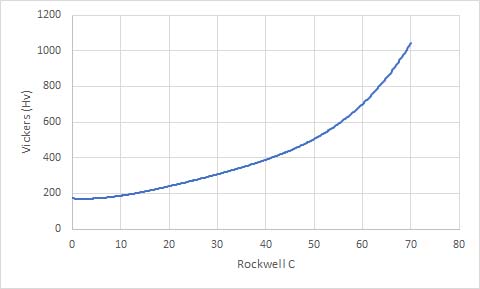

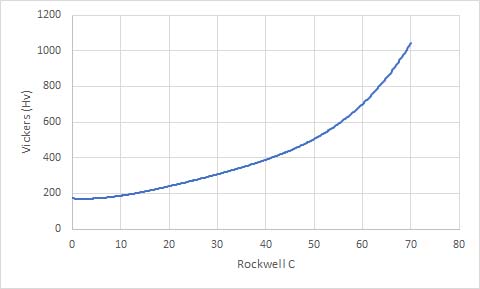

I don't have a tensile strength conversion above 60 Rc, so here is a plot up to 70 Rc comparing to Vickers which is similar to the plot above but to higher hardness:

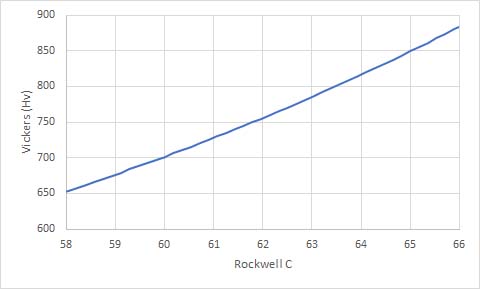

However, even a curve is more or less a straight line if on a small enough scale. And in the 58-66 Rc range we are talking about, the trend is very linear:

Therefore I wouldn't be too concerned about there being greater increases in strength from 61 to 63 Rc than from 58 to 60 Rc, as the difference is pretty small.

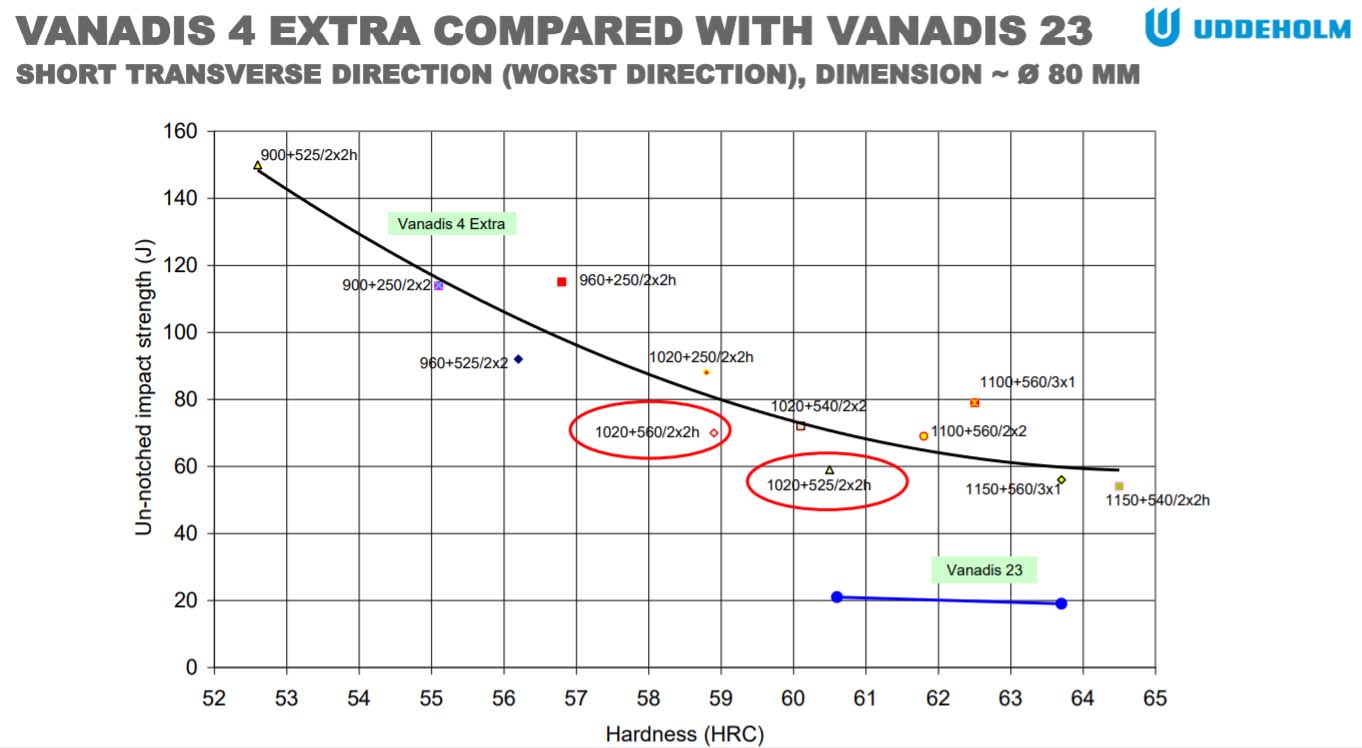

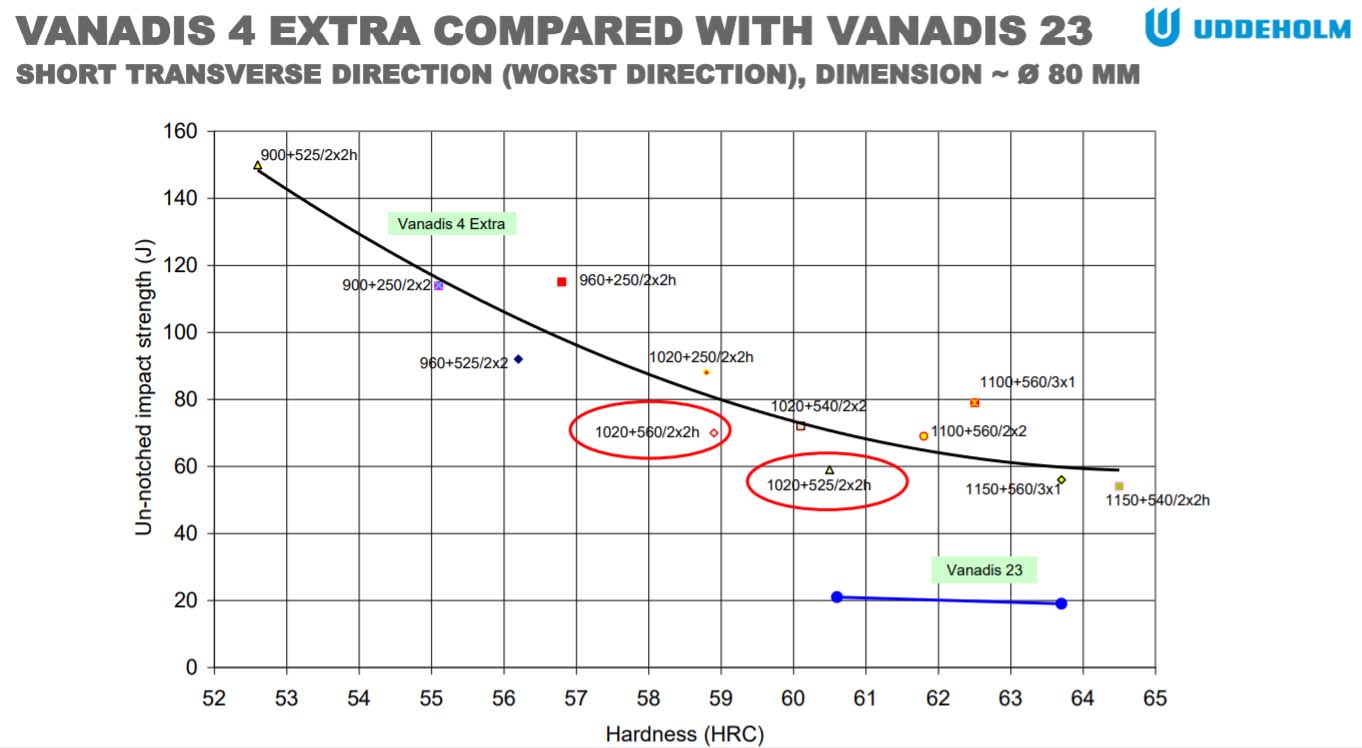

As it turns out, toughness often starts to level off at high hardness, rather than an acceleration to zero. One example is the CruForgeV data I posted before. Or in this data on Vanadis 4 Extra:

Therefore I maintain that the low toughness value for 8670 at ~64 Rc was due to insufficient tempering and not due to an inherent hardness effect.