Hello everyone!

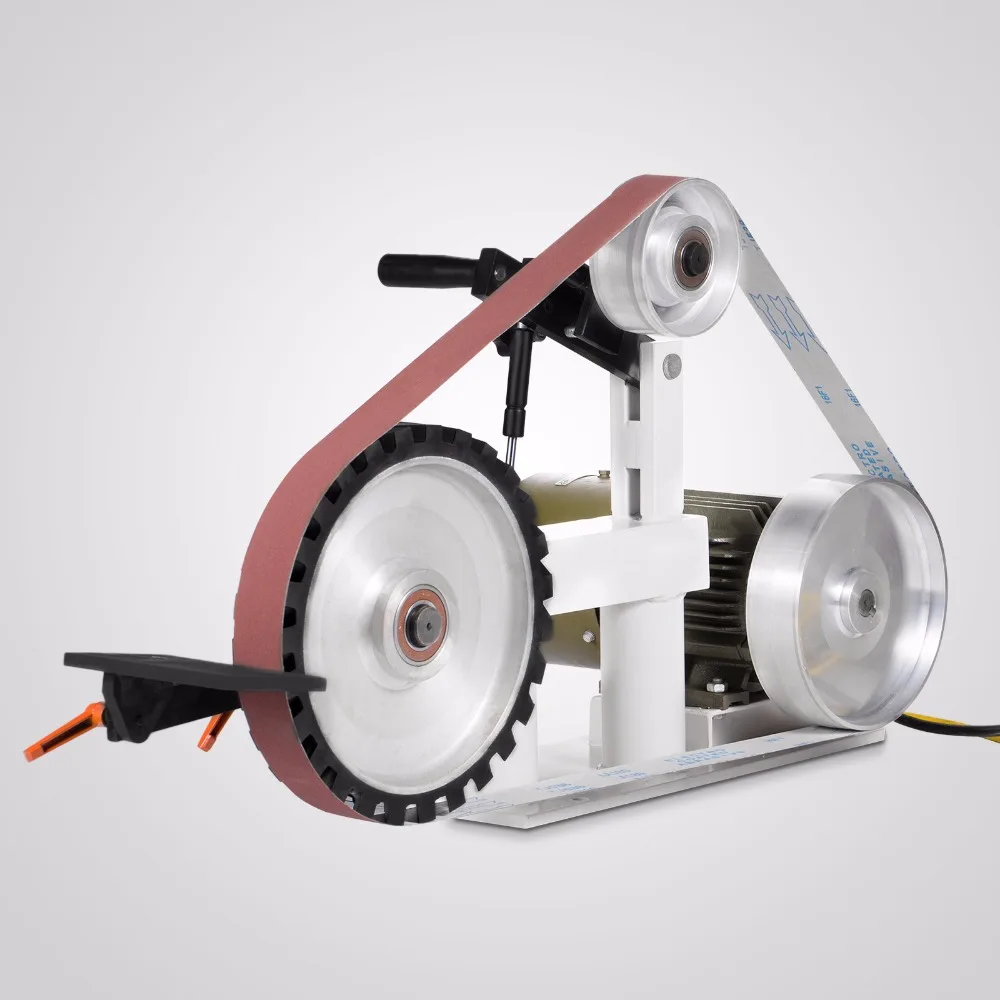

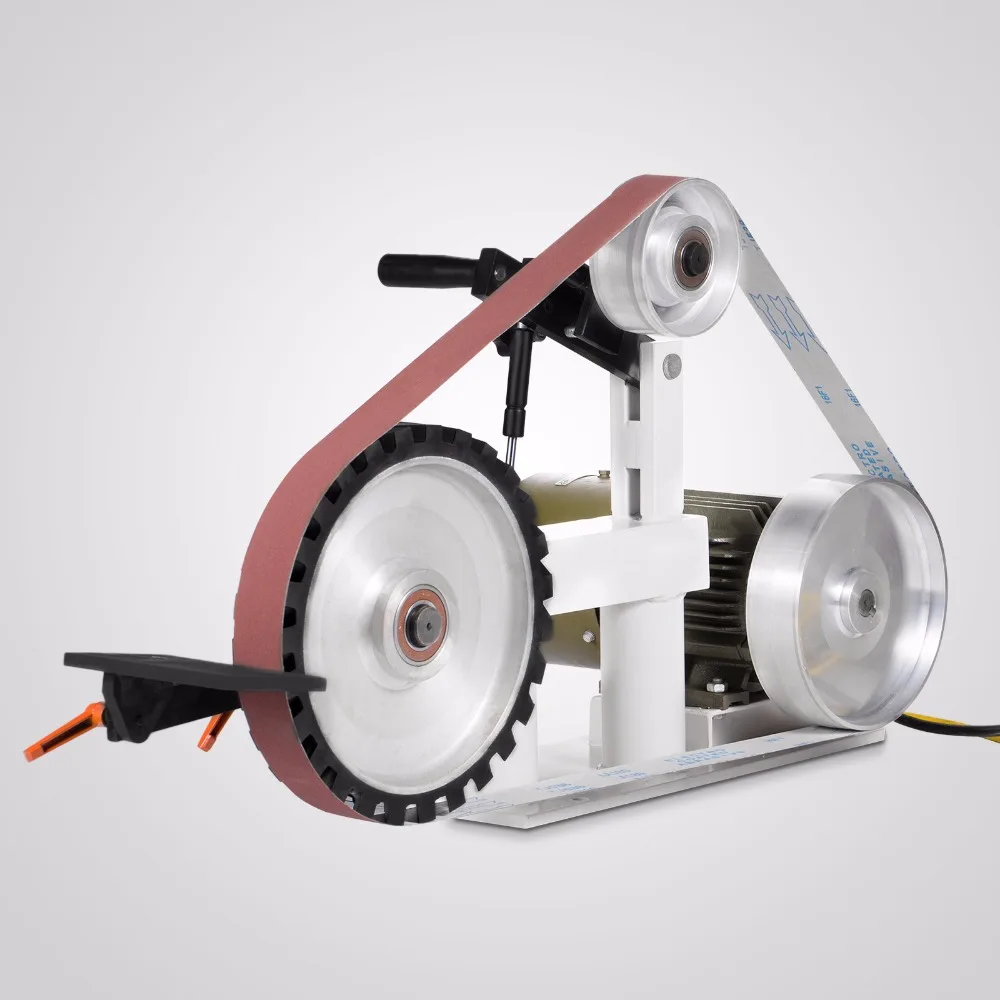

These are available since some time now, but there aren't really a lof of opinions on it available. Does someone have a unit like this, or know someone who owns one? I found two australian gentlemen who bought it, and both were really pleased with it, and two 5 star ratings on ali. What surprises me that the only opinions I found were positive, and no negatives till now. They use big sealed Japanese made NSK bearings, the sheet metal looks like 1/2" or thicker, has a gas spring, seems well built and thought out, etc. So it doesn't look like typical Chinese junk.

I am talking about this one, lots of sellers have them though:

https://www.aliexpress.com/item/-/32845409414.html?spm=a2g0s.8937460.0.0.74bd2e0efHb14J

https://www.aliexpress.com/item/-/32845409414.html?spm=a2g0s.8937460.0.0.74bd2e0efHb14J

For about 950$ delivered I would get a unit with 2hp motor, VFD, 12" contact wheel, platen attachment, and small wheel attachment with two small (1", 1.6") wheels. Locally I can't even get the materials to make one similar for this price, not to speak about time involved and labour costs.

So if someone has some kind of info on these, than please don't hold back!

PS: I know, buying anything Chinese can be hit or miss, that's why I am asking if someone has more info than myself. For the price, this unit is even than really nice if it needs some tuning before use

These are available since some time now, but there aren't really a lof of opinions on it available. Does someone have a unit like this, or know someone who owns one? I found two australian gentlemen who bought it, and both were really pleased with it, and two 5 star ratings on ali. What surprises me that the only opinions I found were positive, and no negatives till now. They use big sealed Japanese made NSK bearings, the sheet metal looks like 1/2" or thicker, has a gas spring, seems well built and thought out, etc. So it doesn't look like typical Chinese junk.

I am talking about this one, lots of sellers have them though:

For about 950$ delivered I would get a unit with 2hp motor, VFD, 12" contact wheel, platen attachment, and small wheel attachment with two small (1", 1.6") wheels. Locally I can't even get the materials to make one similar for this price, not to speak about time involved and labour costs.

So if someone has some kind of info on these, than please don't hold back!

PS: I know, buying anything Chinese can be hit or miss, that's why I am asking if someone has more info than myself. For the price, this unit is even than really nice if it needs some tuning before use

Last edited: