- Joined

- Feb 1, 2012

- Messages

- 424

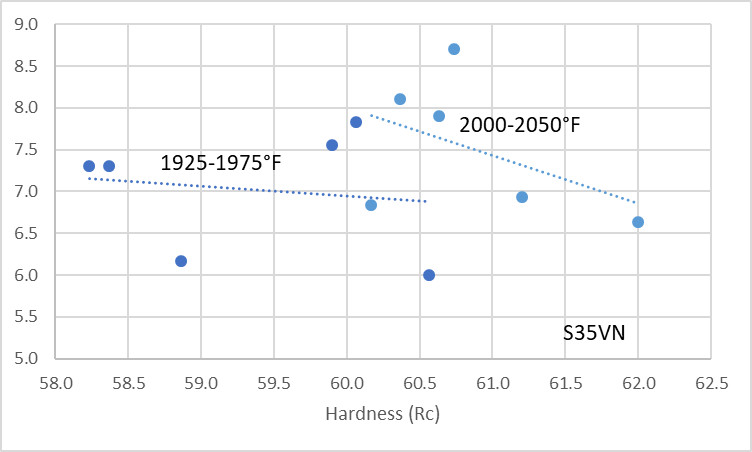

It seems like both of these steels are competitive in pricing and availability. It seems like CPM-154 is tougher, and CPM-S35VN is better in wear resistance. Is that accurate? I will most likely make test blades in both in the future in a HRC range of 60-62 w/ cryogenic treatment. I'm curious which you would choose and for what reasons. Thank you.

Last edited: