- Joined

- Aug 21, 2013

- Messages

- 3,898

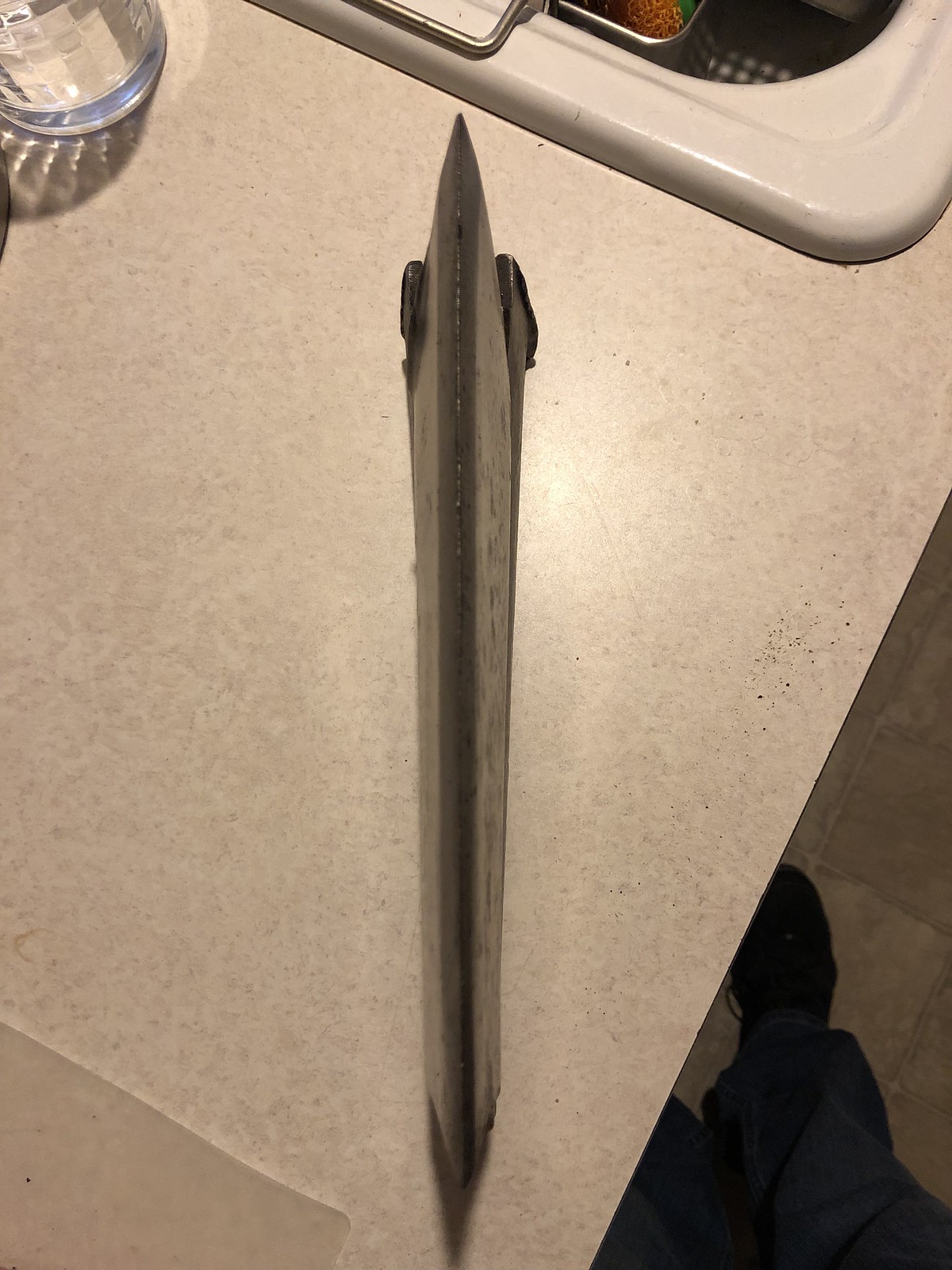

Nice one! Jus weigh the head And you'll know exactly what it is. Or just measure the edge? My guess is a 25.6 or a 25.7. But I actually think its a 25.6 judging from the 26 you have overlayed on top. Both the 25.6 and 25.7 are quite rare.

As a side note: Big steps are made with the presumably Danisch axe. Thats ones even bigger, although I cant say anything about the weight of it at the moment. Hoping for the best, praying for the worst. I've already set aside handle material for the project.

Your guess on the model is as good as mine. Someone did bang on the back of the blade and pushed it out a touch but I've noticed something about their builds that I haven't seen mentioned before (of course, I don't speak Finnish so it's possible it's been discussed a lot and I don't know it).

Both of their bits are noticeably thinner overall at the toes than at the heels.

What would the design function of that be?

A big Danish axe is another thing I wouldn't find around here!