Jay Fisher wrote some interesting opinion about CPM-Magnacut on his website. I truly don't understand why such a famous maker can be so ignorant about the subject he always claimed to be an expert...

"

MagnaCut is another recent invention, claiming to be the very best steel possible for knives. The NEW steel, the be all end all answer to steel needs for knives. Okay, I've seen this hype stuff for years, and there are a lot of truly good steels, high alloy steels, and powder metal technology steels that come and go. I still remember 440V and CPM S60V... but that's no matter. So this is another try. Only this one has very little chromium in it, making it "more stainless?" What? Don't know if I believe that, but hey, so what. It's on a comparagraph, so it's got to be true, right? Gosh, this type of generalized, non-specific advertising has gone on for decades in this field, and it really gets old. This bar is higher than that bar, this line is lower here, and the manufacturer of this steel doesn't even list an accurate cryogenic processing guide of this steels heat treatment! They claim on their own white sheet, "A freezer treatment at -10°F (-23°C) has no effect unless performed directly after the quench with no delay." What the heck are they talking about? Putting the steel in the bottom drawer of your refrigerator rightly next to your ice cream? To a professional heat treater (I am), this is ludicrous coming from the company who sells this stuff. Heck, a good cryogenic treatment might mean this steel actually could perform better than any other, but you'll never find that out from the foundry!

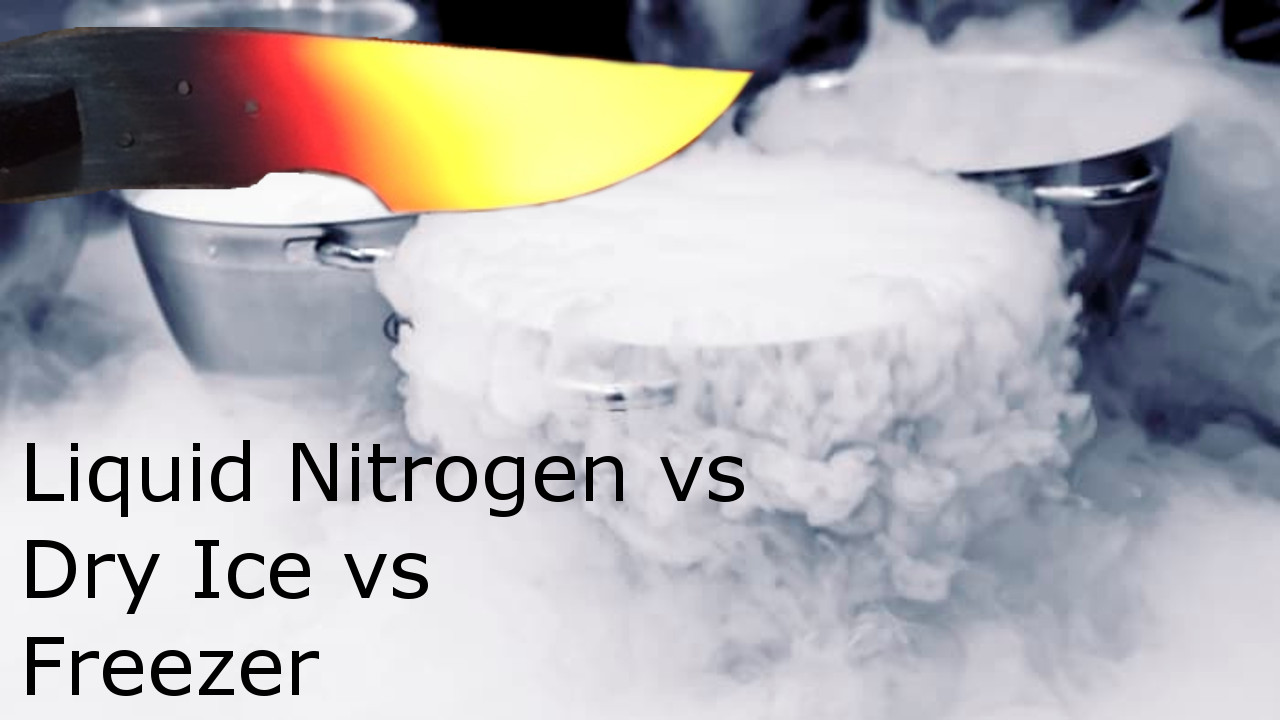

Why? First, they know that the guys that swallow these comparagraphs only have a food refrigerator-freezer to do their "treatment" in, and second, they don't want their steel to have too much longevity, because they'll never sell enough of it. Best to leave out the detailed cryogenic treatment information, and just come up with a deepfreeze blade that holds an edge a bit longer than the next knife...In any case, this is just one of the latest pop steels (my gosh, in my 40 year career I've seen so many) and I think I'll just wait out the next best steel that actually only requires an ice pack next to a cold beer to become fully "treated." Sigh...Just so you know, all of these steels MUST HAVE DEEP CRYOGENIC TREATMENT to reach their full potential, and I seem to be the only guy bringing that up. And Crucible steel does chart a liquid nitrogen quenching, but they don't tell you how long, or how fast or slow to get there, or how many times it needs to happen, or any other but a generalized information chart about "cold treatments." And what do you get with a cryogenic "cold treatment?" 62 Rockwell, barely file-hard. Not too encouraging; I wonder what their process is? Nobody asks a career heat treater and knifemaker, just some punks that work in the advertising department and juggle computer programs to "invent" new steel alloy sets. Had enough? Okay, I'll stop now. I'm into BR5-49 anyway, with a "Supercut" haircut."

"

MagnaCut is another recent invention, claiming to be the very best steel possible for knives. The NEW steel, the be all end all answer to steel needs for knives. Okay, I've seen this hype stuff for years, and there are a lot of truly good steels, high alloy steels, and powder metal technology steels that come and go. I still remember 440V and CPM S60V... but that's no matter. So this is another try. Only this one has very little chromium in it, making it "more stainless?" What? Don't know if I believe that, but hey, so what. It's on a comparagraph, so it's got to be true, right? Gosh, this type of generalized, non-specific advertising has gone on for decades in this field, and it really gets old. This bar is higher than that bar, this line is lower here, and the manufacturer of this steel doesn't even list an accurate cryogenic processing guide of this steels heat treatment! They claim on their own white sheet, "A freezer treatment at -10°F (-23°C) has no effect unless performed directly after the quench with no delay." What the heck are they talking about? Putting the steel in the bottom drawer of your refrigerator rightly next to your ice cream? To a professional heat treater (I am), this is ludicrous coming from the company who sells this stuff. Heck, a good cryogenic treatment might mean this steel actually could perform better than any other, but you'll never find that out from the foundry!

Why? First, they know that the guys that swallow these comparagraphs only have a food refrigerator-freezer to do their "treatment" in, and second, they don't want their steel to have too much longevity, because they'll never sell enough of it. Best to leave out the detailed cryogenic treatment information, and just come up with a deepfreeze blade that holds an edge a bit longer than the next knife...In any case, this is just one of the latest pop steels (my gosh, in my 40 year career I've seen so many) and I think I'll just wait out the next best steel that actually only requires an ice pack next to a cold beer to become fully "treated." Sigh...Just so you know, all of these steels MUST HAVE DEEP CRYOGENIC TREATMENT to reach their full potential, and I seem to be the only guy bringing that up. And Crucible steel does chart a liquid nitrogen quenching, but they don't tell you how long, or how fast or slow to get there, or how many times it needs to happen, or any other but a generalized information chart about "cold treatments." And what do you get with a cryogenic "cold treatment?" 62 Rockwell, barely file-hard. Not too encouraging; I wonder what their process is? Nobody asks a career heat treater and knifemaker, just some punks that work in the advertising department and juggle computer programs to "invent" new steel alloy sets. Had enough? Okay, I'll stop now. I'm into BR5-49 anyway, with a "Supercut" haircut."