Less than a week ago I was at REI and I noticed a 535 sitting in a display case. After checking it out I bought with the intent of taking it on an upcoming hiking trip. The knife is awesome and I love the axis lock. This is the third axis lock knife in my collection now. That said I've never had any trouble with the omega springs until now. Less than a week later I managed to break both the omega springs in the 535. I'm pretty sure it was my fault though. The 535 has a much tighter action out of the box than my 810 or 940-1 and I've been flicking it open rather than opening it normally. Given the light weight of the knife I think flicking the 535 shocks the springs more severely than with other benchmades (lighter blade = higher speed flick = shock). Anyway BM's customer service is awesome and I wouldn't hesitate to send it back but my trip is in a week and I'm a tinkerer so after some internet sleuthing I decided to make my own replacements.

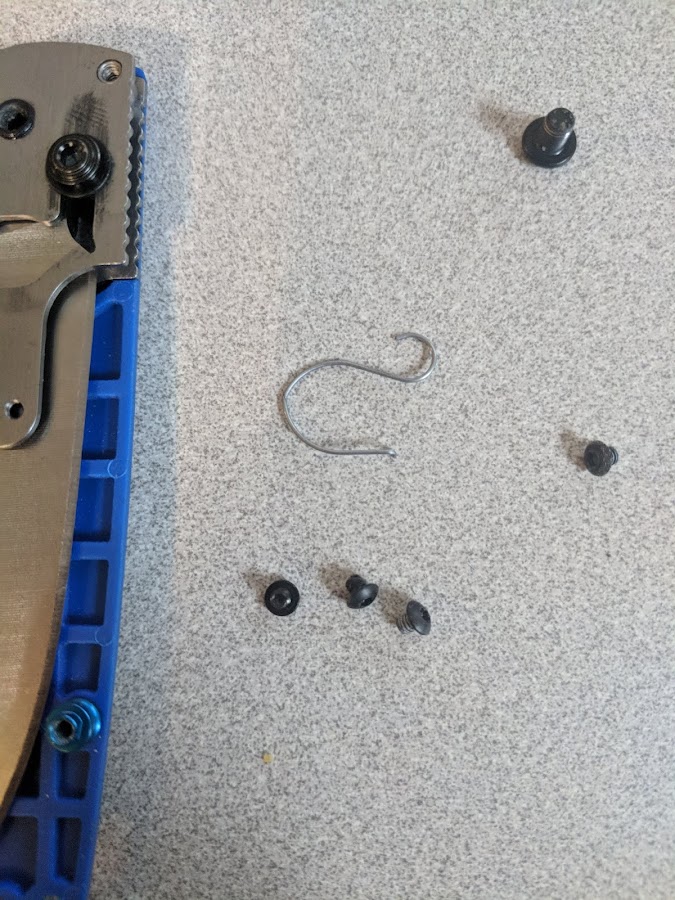

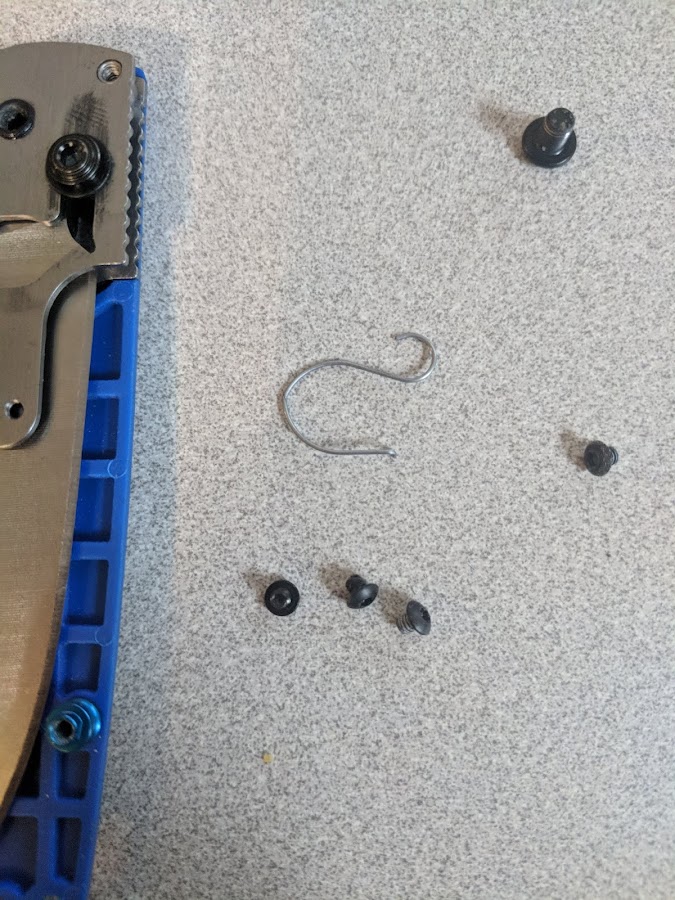

Looking at Benchmade's (broken) omega spring:

The spring measures a consistent .021 inch OD thickness throughout. It’s shiny so I am guessing it's stainless.

Requirements for making a new spring:

Needs to be hardened, spring tempered steel in the .020-.025 OD range.

Options:

Music Wire - The internet tells me this is a popular choice for homemade springs. I picked some up from Hobby Lobby for $2 a pack in both .020 and .025 thicknesses. It's made by K&S Metals and the specs on their website indicate that their music wire is made from phosphate coated, spring tempered, high-carbon steel. My only concern for this material would be the lack of corrosion resistance. I’m not sure if the phosphate coating is to help that or not. My guess is that benchmade probably uses stainless for this reason. The measured thickness is very accurate and consistent throughout.

Memory Wire - This is a jewelry making wire I saw someone on youtube use to make some replacement omega springs. I bought some in .025" thickness from Hobby Lobby while I was there for $3.50. I looked up the specs on the manufacturer's website and it is "hard tempered", silver plated, carbon steel wire. Working with it is very similar to the music wire so I'm inclined to think it might just be plated music wire. That said its thickness isn't nearly as consistent as the music wire so that is one concern. The other is that I'm not sure if "hard tempered" means "spring tempered" or even if either of those things have any real meaning anyways. No idea what the corrosion resistance is but if it is silver plated I'd think it would be susceptible to tarnish.

316LVM Stainless Spring Steel - I ordered this from online in .021 thickness. I wanted to get something that would represent my best guess at to what Benchmade is actually using for their omega springs. I'll get this in the mail later this week.

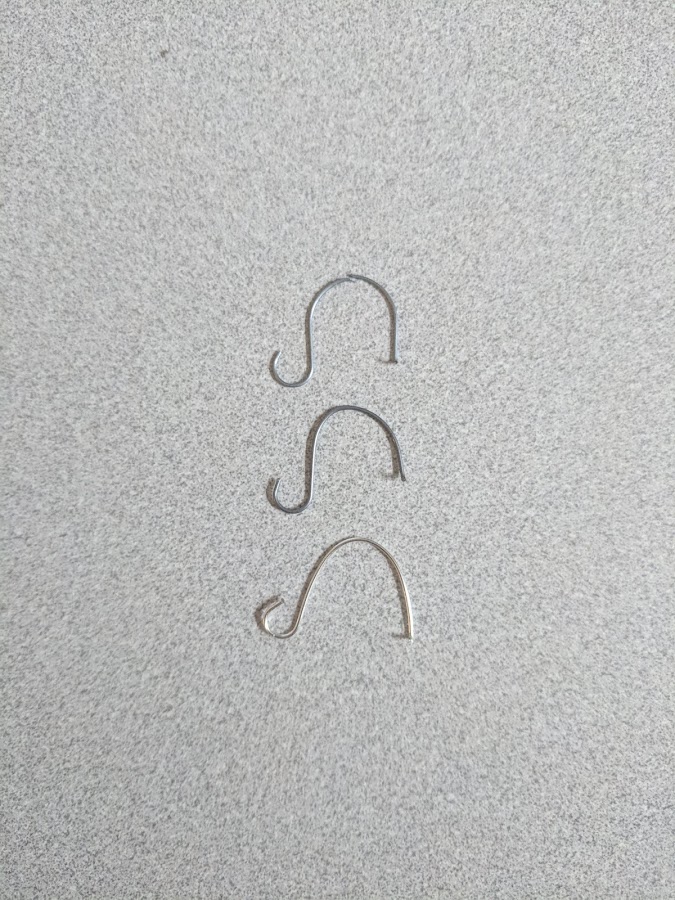

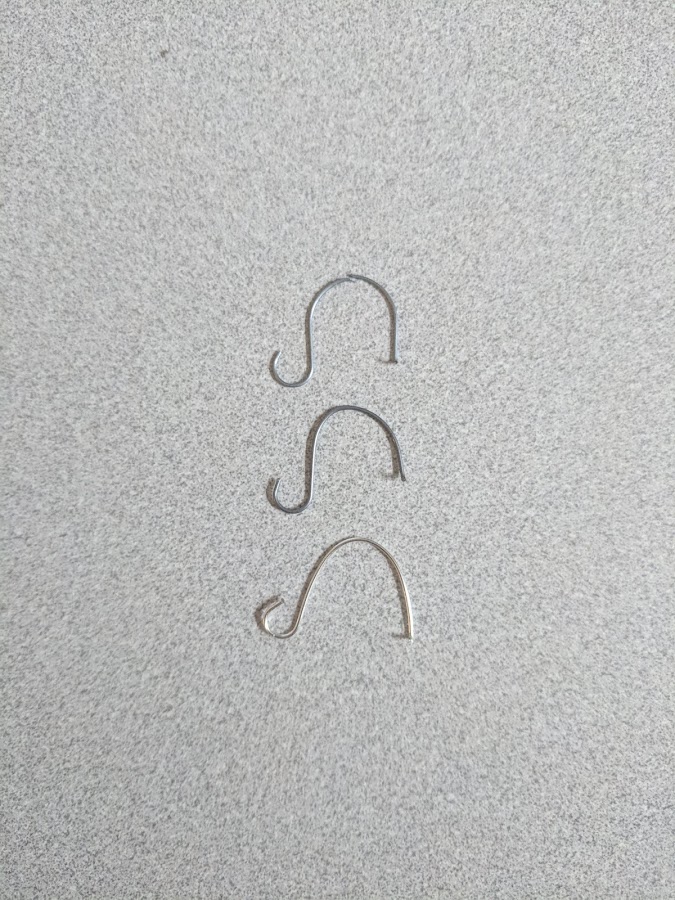

Here are the springs next to each other:

First is the broken Benchmade spring, then the music wire spring and lastly the memory wire spring.

To make the spring I used a pair of jewelry pliers and a pair of needle nose pliers. I made the large bend by wrapping the wire around a pen that had the diameter I was looking for. I might try making a jig to get more consistent results.

After making several and tweaking them until I thought I matched the original as best I could, I installed a set of the .025 music wire springs. After using that for a day I decided they were too stiff and I switched them out for the .020 music wire springs. This is what I have in there now. The action feels a touch lighter than it did before, but very similar to my other axis locks.

I’ll see if I can break these springs in the next couple days and then install the memory wire and do the same, and then 316 stainless. Anyone else played around with making their own springs?

Looking at Benchmade's (broken) omega spring:

The spring measures a consistent .021 inch OD thickness throughout. It’s shiny so I am guessing it's stainless.

Requirements for making a new spring:

Needs to be hardened, spring tempered steel in the .020-.025 OD range.

Options:

Music Wire - The internet tells me this is a popular choice for homemade springs. I picked some up from Hobby Lobby for $2 a pack in both .020 and .025 thicknesses. It's made by K&S Metals and the specs on their website indicate that their music wire is made from phosphate coated, spring tempered, high-carbon steel. My only concern for this material would be the lack of corrosion resistance. I’m not sure if the phosphate coating is to help that or not. My guess is that benchmade probably uses stainless for this reason. The measured thickness is very accurate and consistent throughout.

Memory Wire - This is a jewelry making wire I saw someone on youtube use to make some replacement omega springs. I bought some in .025" thickness from Hobby Lobby while I was there for $3.50. I looked up the specs on the manufacturer's website and it is "hard tempered", silver plated, carbon steel wire. Working with it is very similar to the music wire so I'm inclined to think it might just be plated music wire. That said its thickness isn't nearly as consistent as the music wire so that is one concern. The other is that I'm not sure if "hard tempered" means "spring tempered" or even if either of those things have any real meaning anyways. No idea what the corrosion resistance is but if it is silver plated I'd think it would be susceptible to tarnish.

316LVM Stainless Spring Steel - I ordered this from online in .021 thickness. I wanted to get something that would represent my best guess at to what Benchmade is actually using for their omega springs. I'll get this in the mail later this week.

Here are the springs next to each other:

First is the broken Benchmade spring, then the music wire spring and lastly the memory wire spring.

To make the spring I used a pair of jewelry pliers and a pair of needle nose pliers. I made the large bend by wrapping the wire around a pen that had the diameter I was looking for. I might try making a jig to get more consistent results.

After making several and tweaking them until I thought I matched the original as best I could, I installed a set of the .025 music wire springs. After using that for a day I decided they were too stiff and I switched them out for the .020 music wire springs. This is what I have in there now. The action feels a touch lighter than it did before, but very similar to my other axis locks.

I’ll see if I can break these springs in the next couple days and then install the memory wire and do the same, and then 316 stainless. Anyone else played around with making their own springs?