- Joined

- Feb 25, 2020

- Messages

- 12

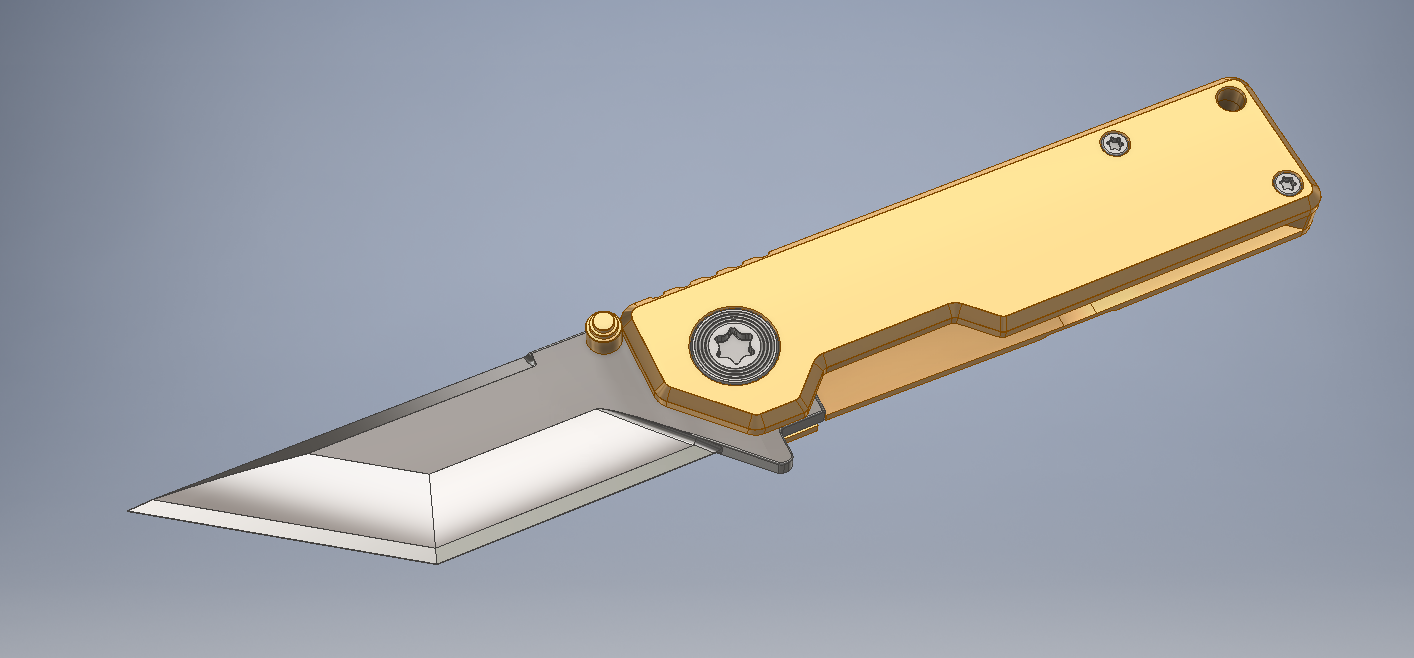

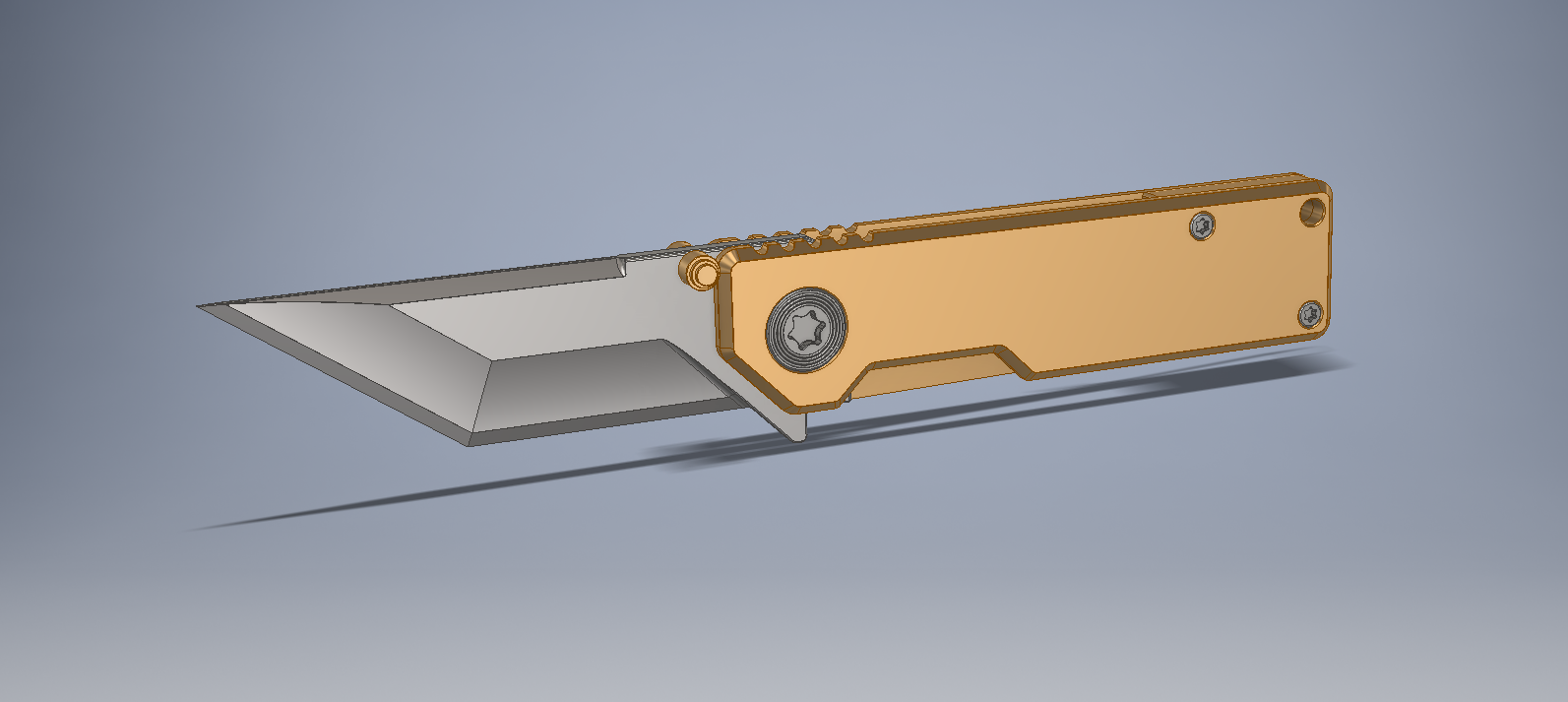

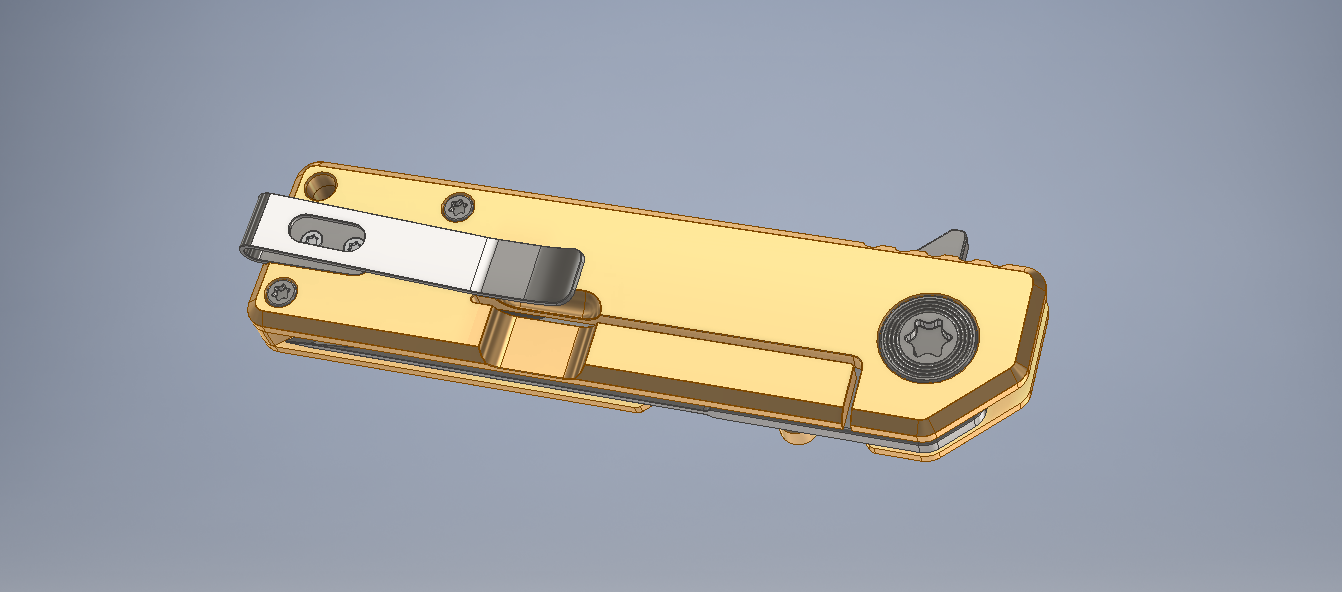

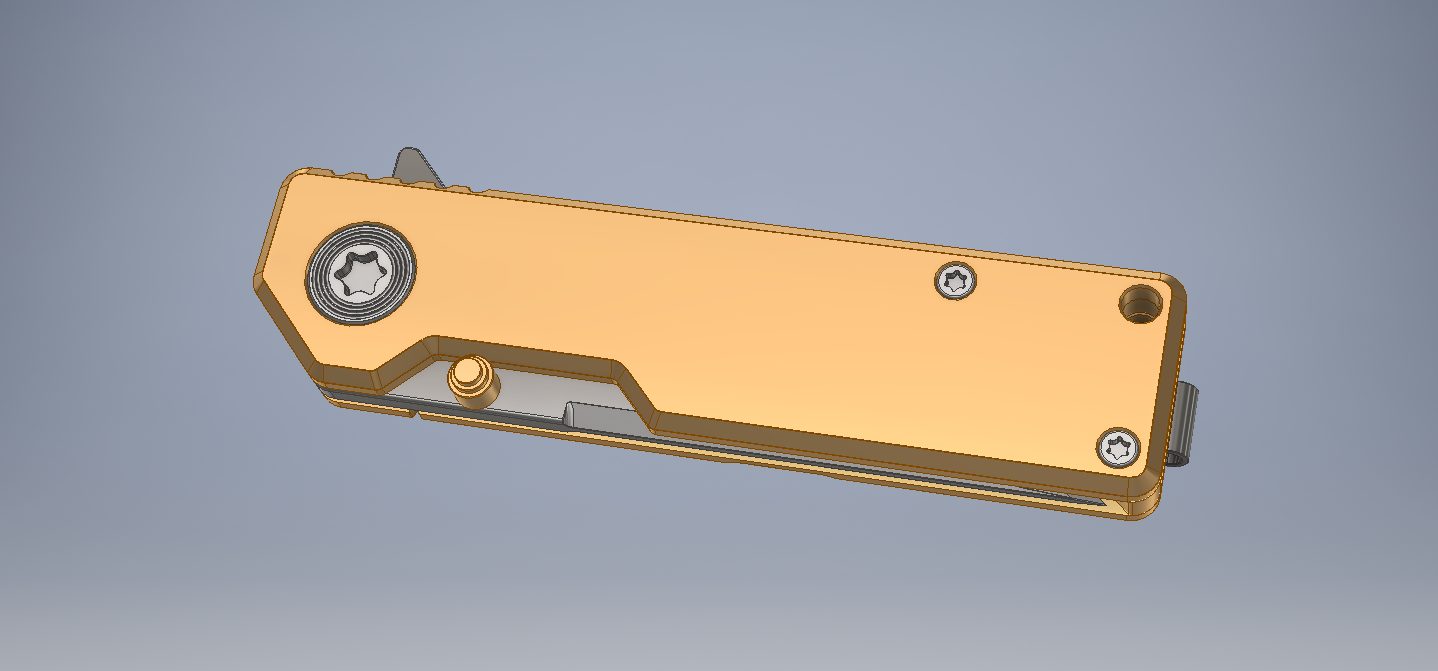

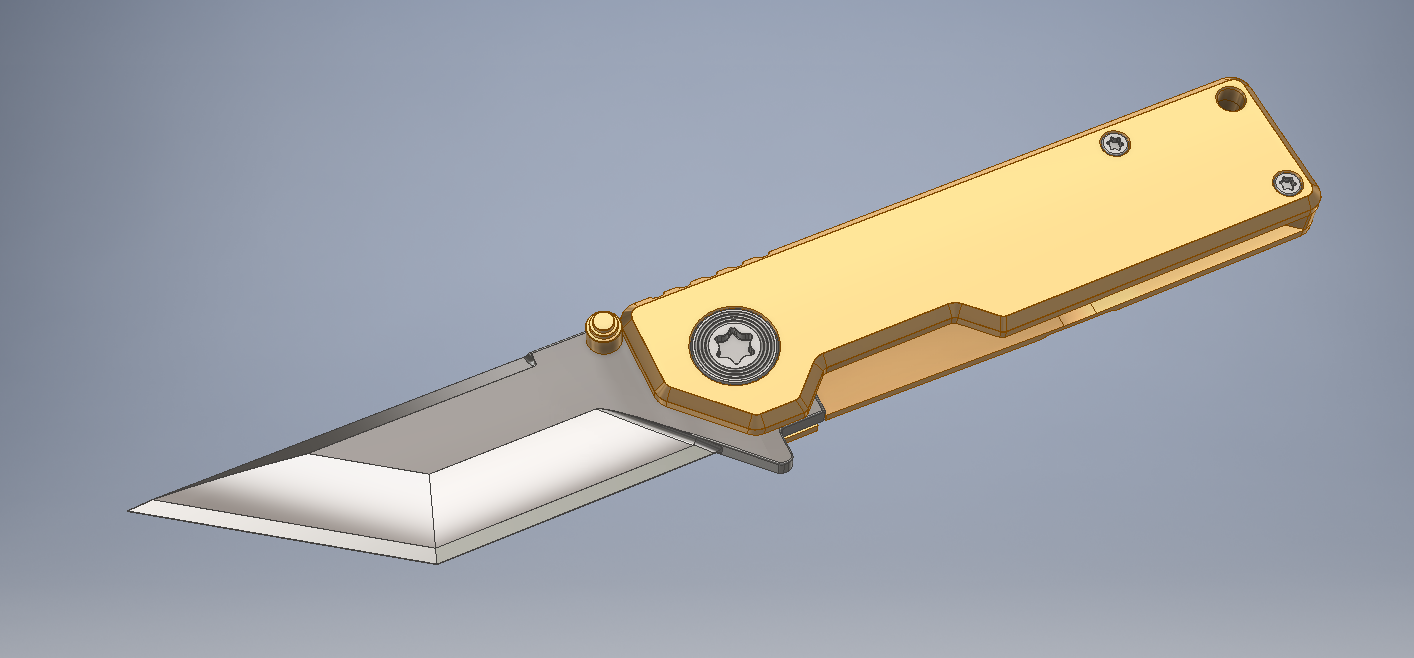

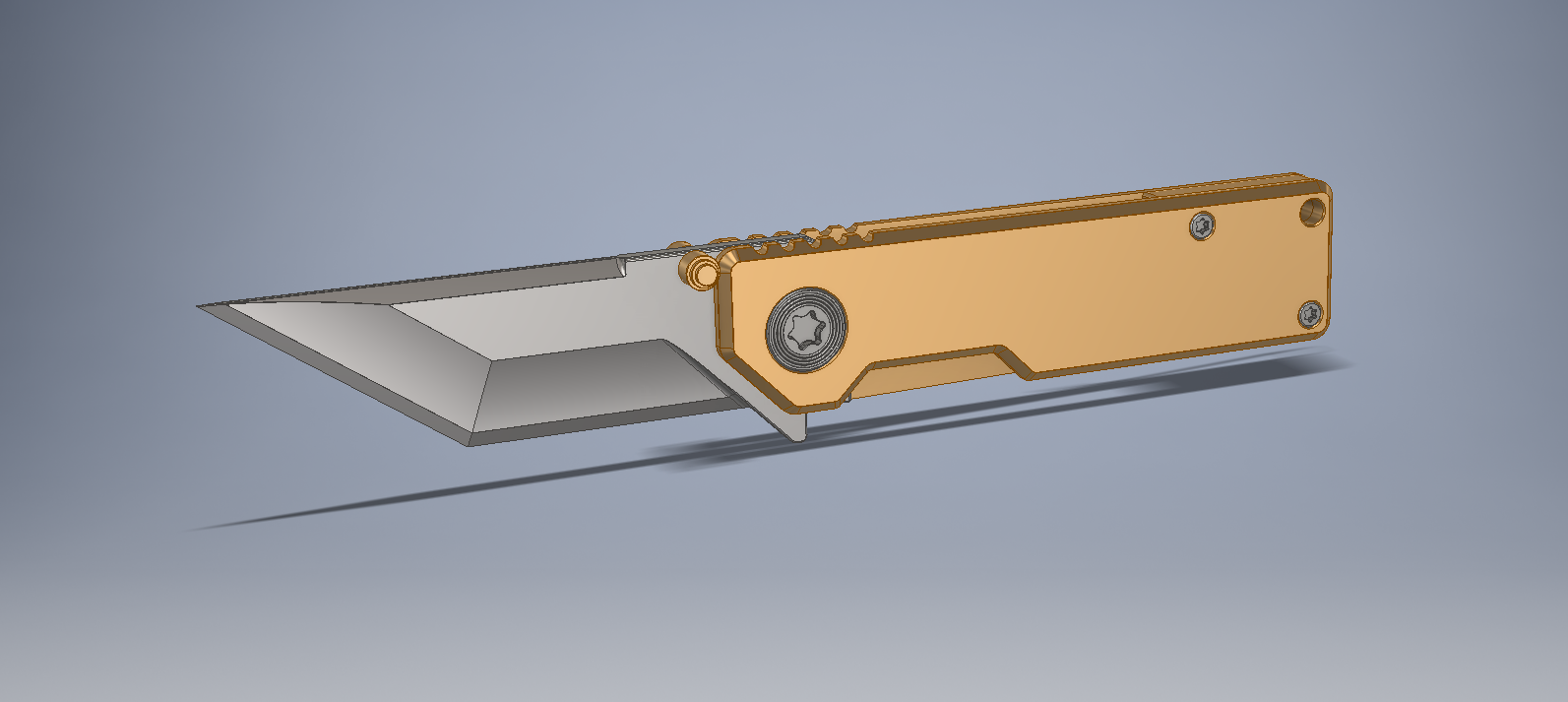

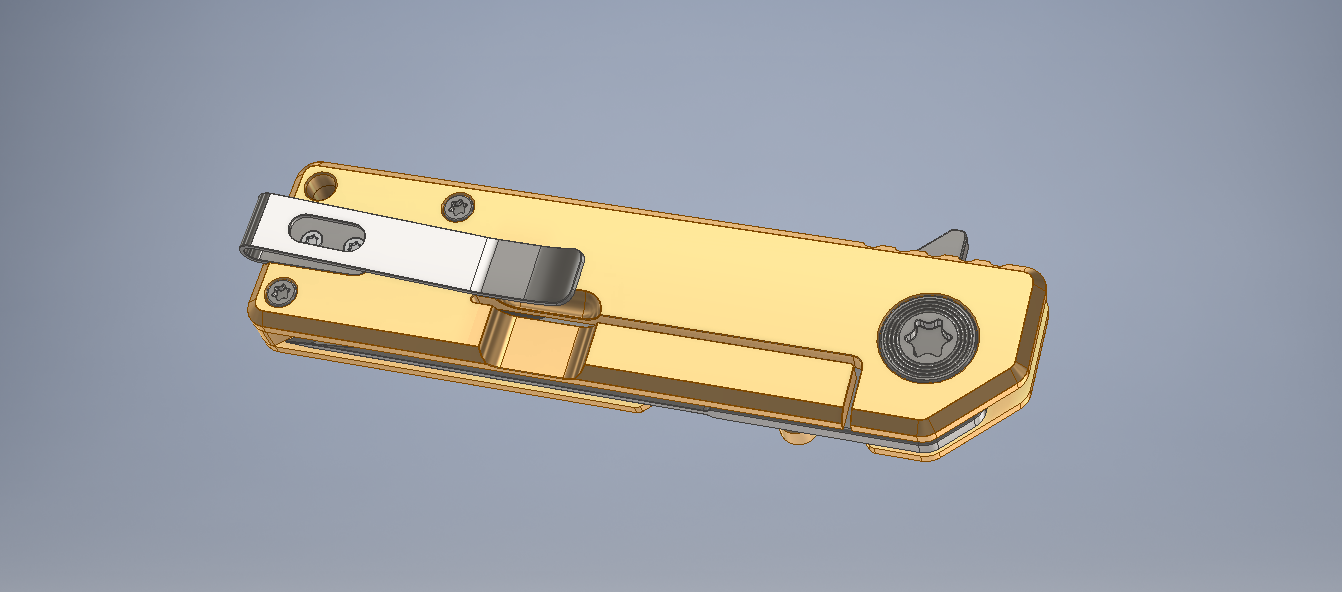

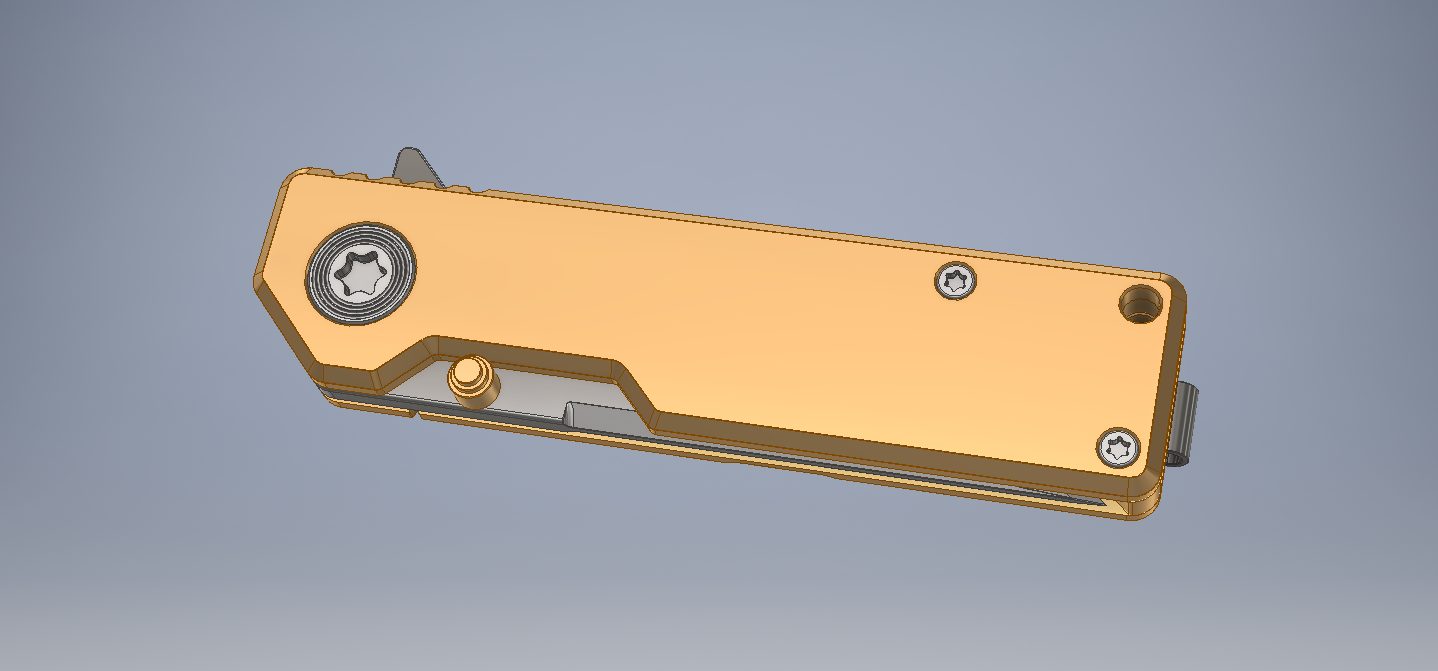

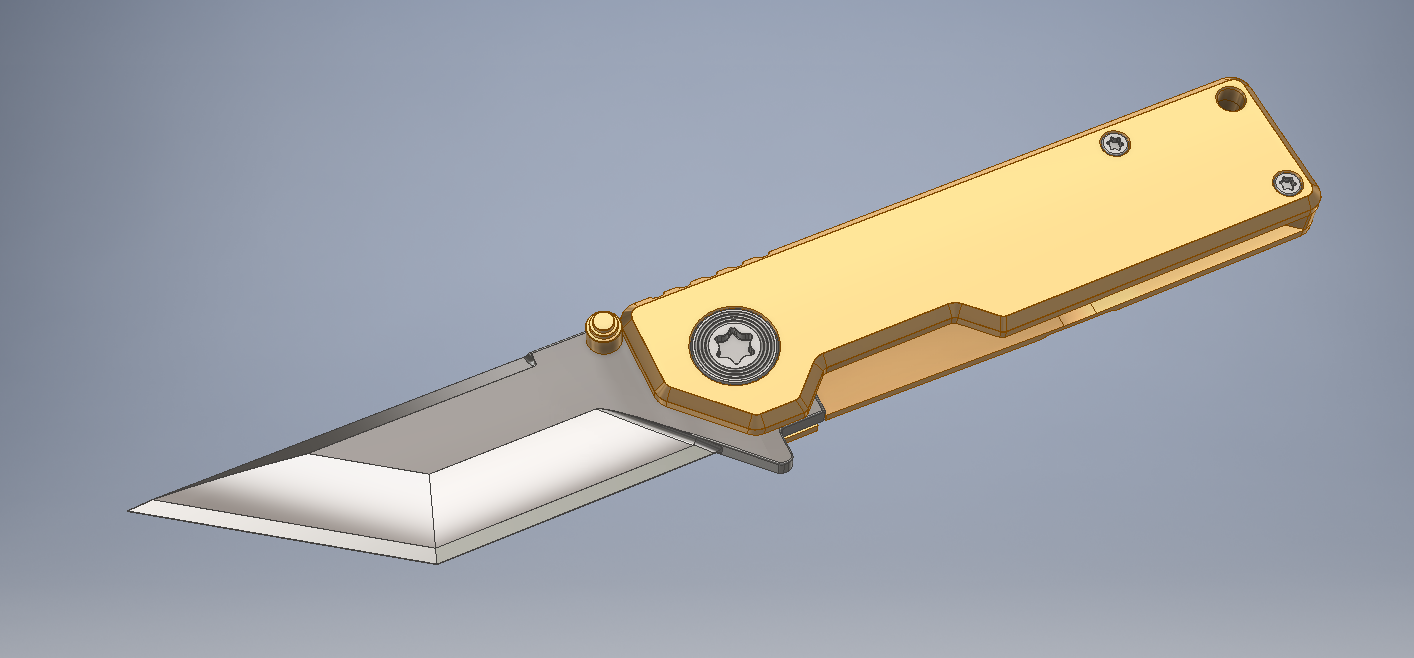

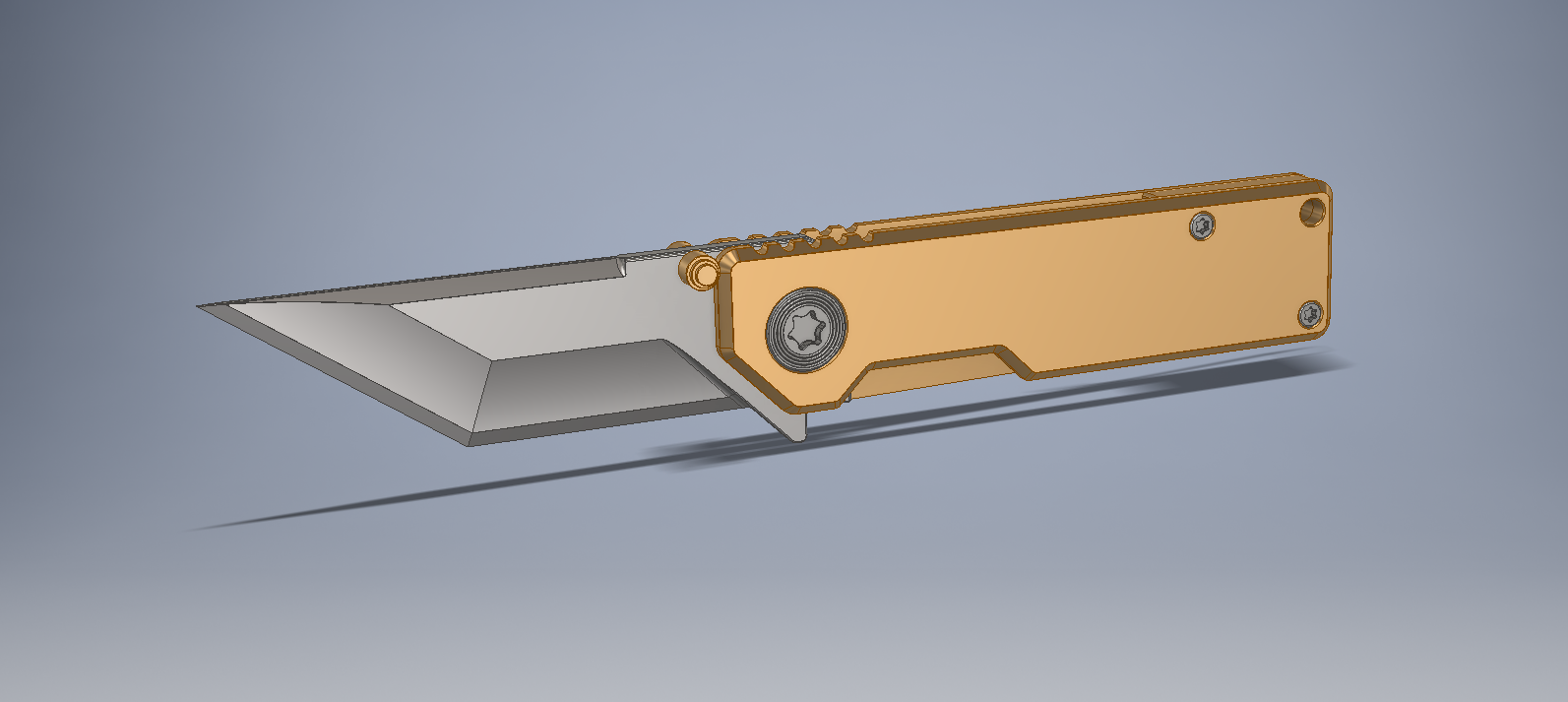

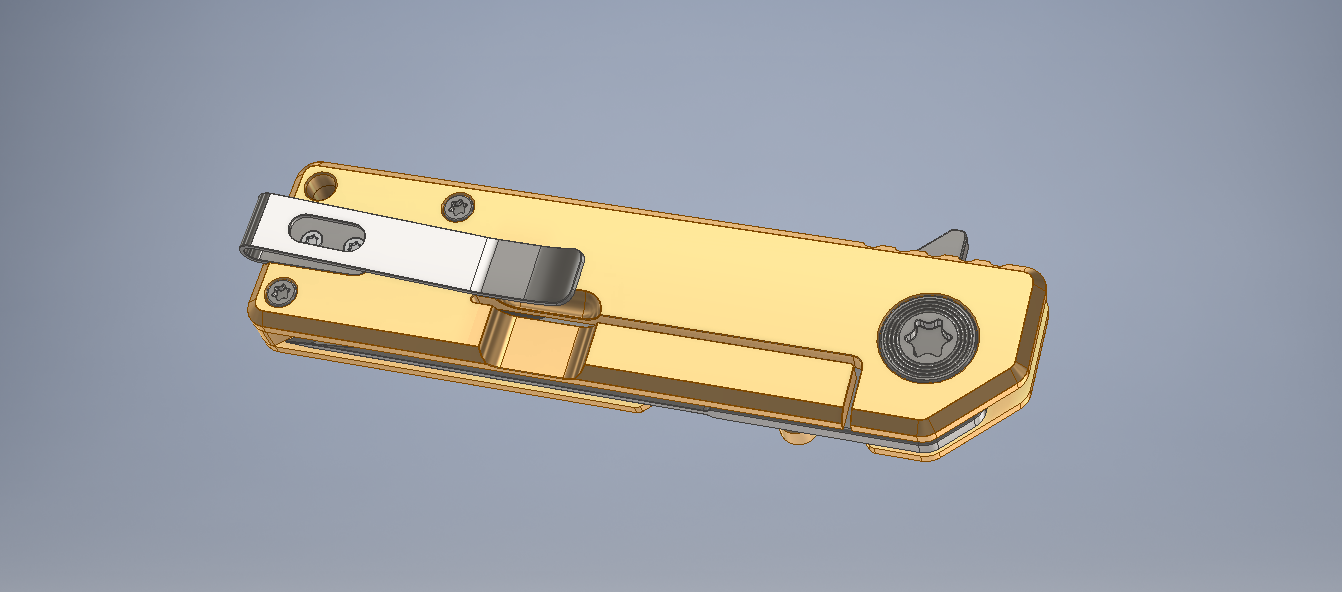

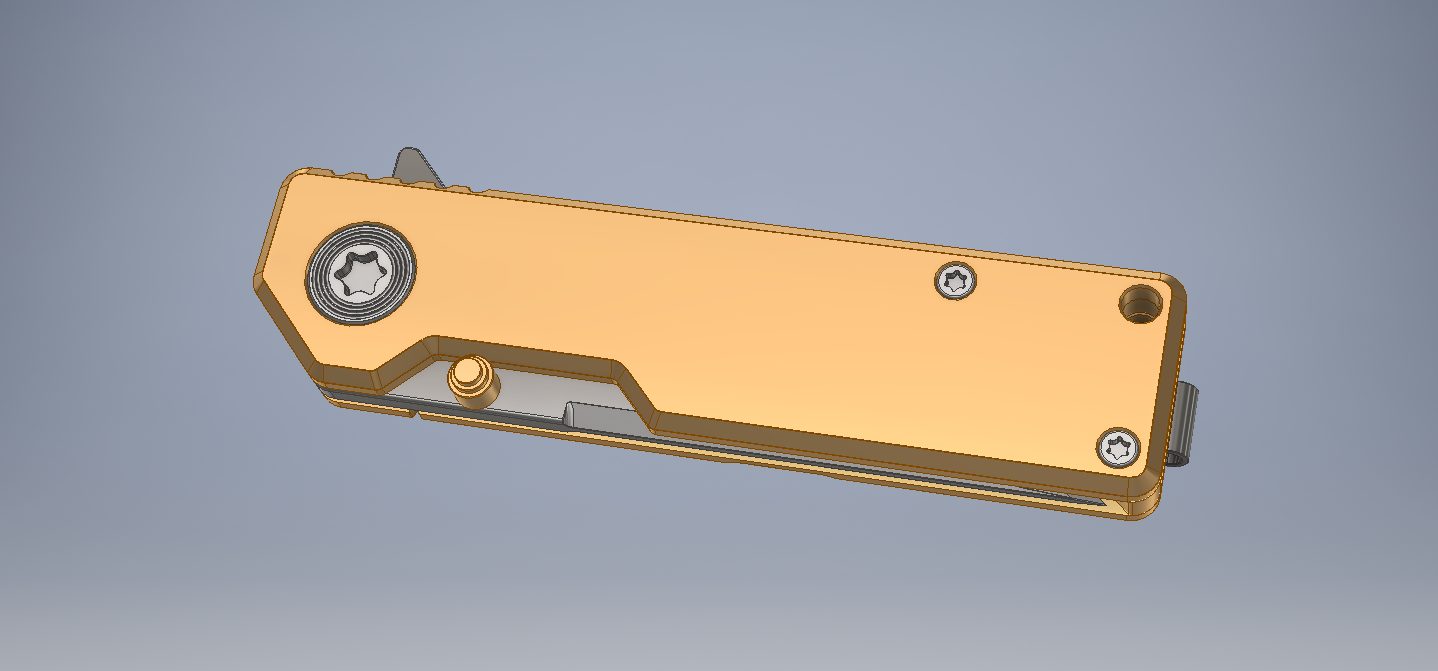

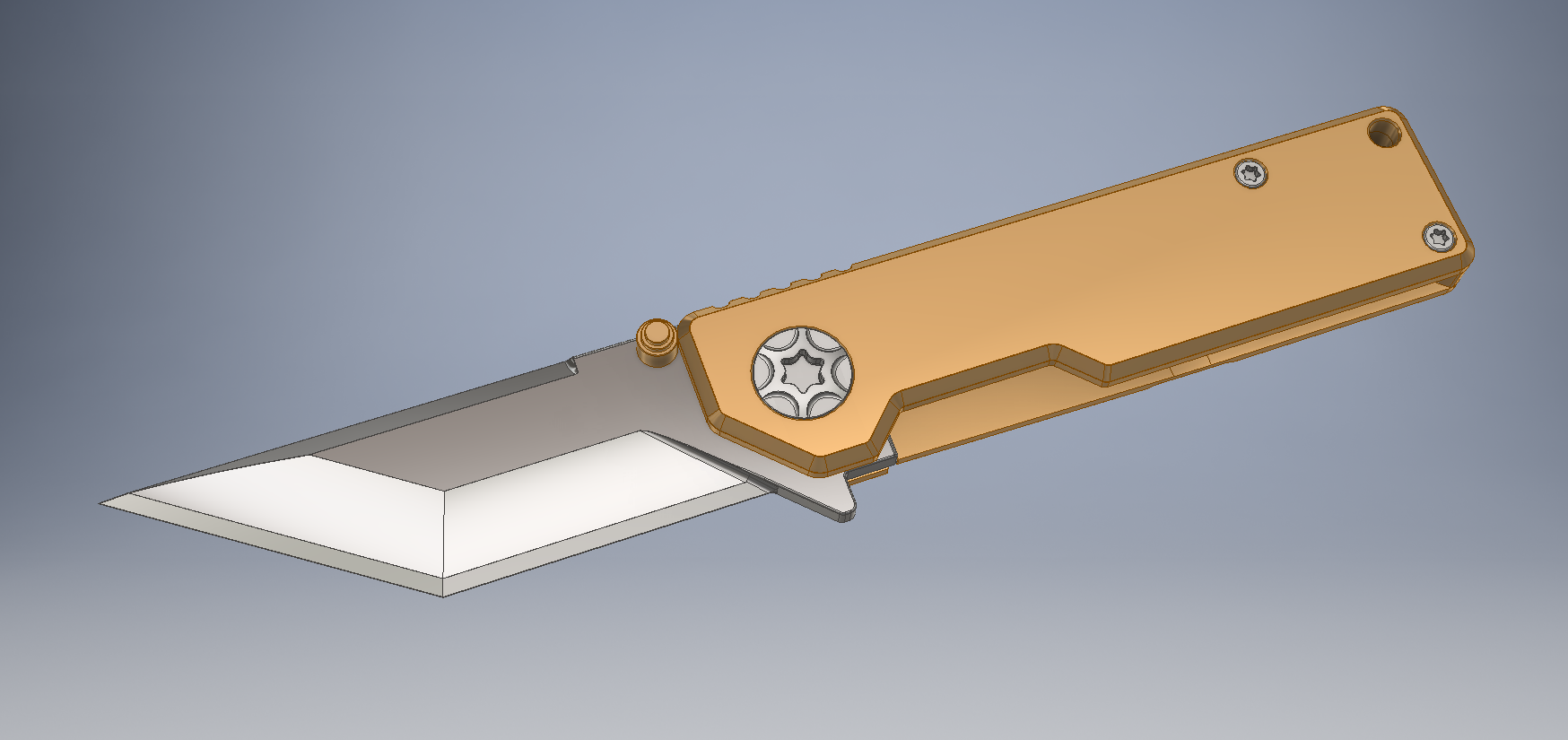

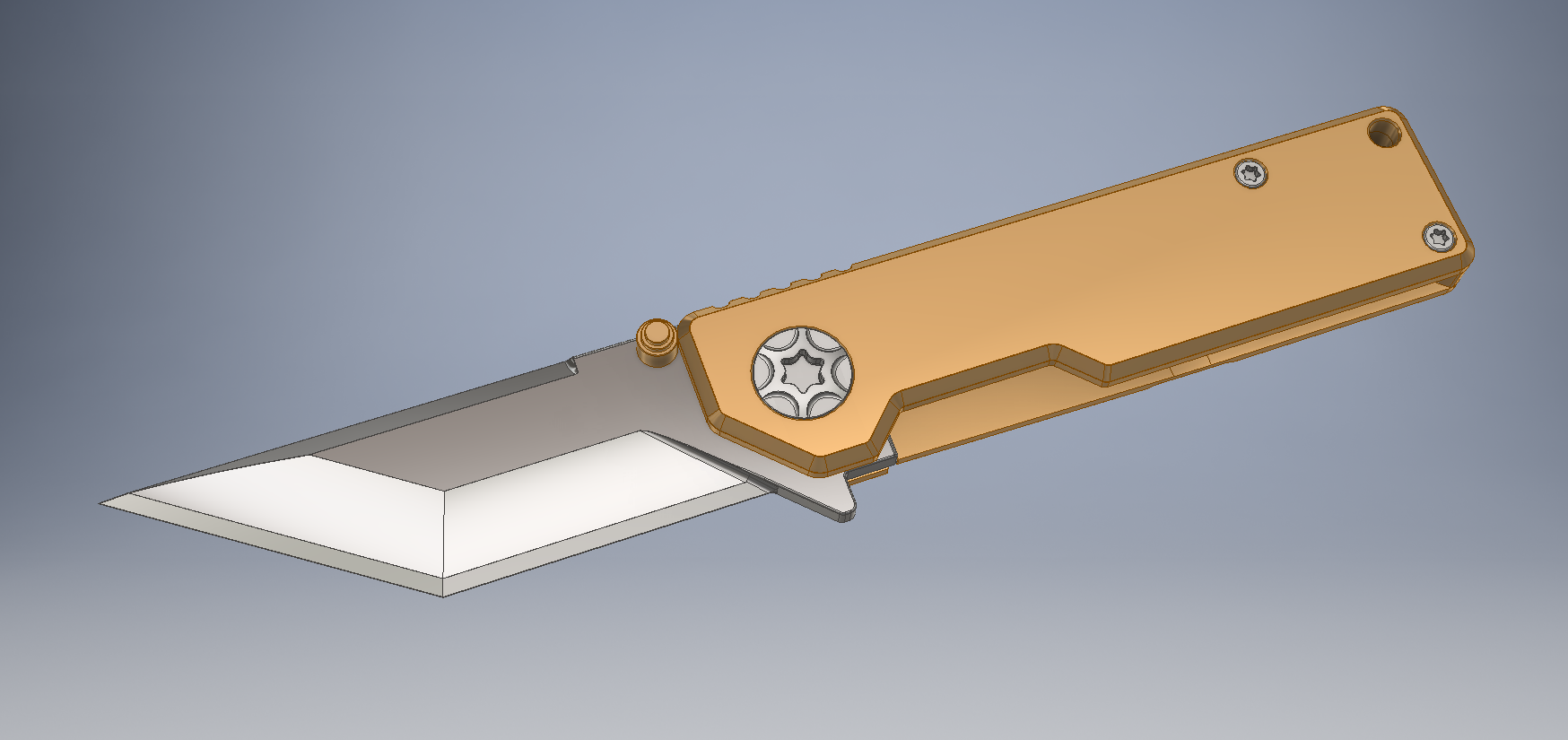

Thank you friend for your support. So far a few more pictures. )

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

And that may be the problem, as I see it. You design a knife as a toy (your yellow knife with the horrible blade shape and square handle goes that way, too). There may be a market of fiddlers who are waiting for such a product. No idea I have. But a knife, in my opinion at least, should be pleasant and efficient to cut things with. No need for outlandish lock systems or such. Good ergos, pleasant aesthetics, sensible geometry and you're on your way.I was thinking the other way, i.e. that an automatic might be an interesting novelty, that people might be interested in just playing with its mechanism, opening and closing it.

And that may be the problem, as I see it. You design a knife as a toy (your yellow knife with the horrible blade shape and square handle goes that way, too). There may be a market of fiddlers who are waiting for such a product. No idea I have. But a knife, in my opinion at least, should be pleasant and efficient to cut things with. No need for outlandish lock systems or such. Good ergos, pleasant aesthetics, sensible geometry and you're on your way.

^this. Most definitely.

well, so far I am just doodling around in autodesk inventor.

I remember when I started in the trades, I had a lot of commentary like that. A laborer, I was in a little bit of awe of the work some of the cabinet makers were doing. My job was cleaning up, hauling materials, delivering cabinets and "holding that right there". I would ask them "how long does it take to get as good as you?", and the guys would look at each other and laugh, then tell me how long they had been making cabinets and doing custom wood work. I remember pointedly asking more than one of them "how long do you think it will take to learn what I need to before I can build cabinets on my own?"

They made a production out of the answer. Their eyes would narrow, they would look at me with slight disgust, and tell me //IF// I ever got good enough to build on my own, it would take about 15-20 years. They would take a pull of their smoke, and then tell me that would ONLY be if I had the skills. Then shake their head with doubt. It was almost a ceremony.

So I worked hard with the best guy the company had for a couple of years, worked on the weekends with another company, and studied on techniques, build procedures, hardware installation, cost to build, estimating materials, etc.

I sold my first full set of completely custom kitchen cabinets, made from raw materials and sheet goods about 3 years after I started in the trades. They took me about a month and half to build, but I got it done. Friends of my client liked the quality so much that they had me build their cabinets when they remodeled immediately after that. About 2 years later I had enough business to rent a small space and buy about (in 1977 dollars) $3000 of equipment.

I don't advertise, and all of my business is referral. I have a 4 month back log of work. I have been in business for myself now for 39+ years. I am glad all the time I didn't listen to those guys. I see those "you may never be as good as me" guys all the time, and the song hasn't changed.

I have a friend that makes knives full time and works part time for insurance availability. He is pretty prolific as day in and day out he makes about 3 - 4 finished knives a month. Using his numbers of about 40 - 50 knives a year, and your requirement of forging 1000 blanks just to see if he MIGHT be able to consider himself a knife maker, (maybe... possibly...), then it would take him well over 20 years just to see if he might have developed he skills to see if he could possibly make a quality knife. Not to be a knife maker, but just to see if he could be. If he falls off the pace of about 45 finished knives a year, then it would be 25 years or more to see if he had the stuff.

Seriously... did it take you 1000 tries to see if you might possibly be able to consider yourself a knife maker? I am surrounded by knife makers here in S. Texas, and I don't know that any of them have worked at the pace described above for over two decades to get to the 1000 knife mark.

My comments are not meant to be a personal criticism because I understand full well that you may have made 1000 knives before you got to your decision to call yourself a qualified knife maker. My thoughts are more that I like to be as encouraging as possible for anyone going into any kind of trades or craft work as a vocation as there are so few doing it these days. As a contractor, I NEVER see young guys wanting to learn to work with their hands. I try to be as encouraging as possible.

BTW, the resemblance to the Kershaw Launch and the Liberty knife is way too much to ignore. I know it is probably impossibly hard to come up with an original design these days, but wow... that's almost embarrassing. Nope... scratch that, it is embarrassing.

Robert