-

The BladeForums.com 2024 Traditional Knife is available! Price is $250 ea (shipped within CONUS).

Order here: https://www.bladeforums.com/help/2024-traditional/

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New from Worksharp: Precision Adjust Knife Sharpener

- Thread starter AFAustin

- Start date

- Joined

- Jun 4, 2010

- Messages

- 6,642

It's just me. I have the Edge Pro Apex, (and most of the accoutrements, including the Diamond Matrix hones), and even have it fastened in place alongside my shop sink. It really couldn't be more convenient unless it sharpened the knives automatically and then cleaned itself off.

I think it's just that I somehow find myself disinclined to stand there pushing and pulling the guide rod across the bevel for a certain number of strokes, flip it over and do the same on the other side. Then wipe the blade, the table etc before changing the stone or changing the angle, whatever.

Perhaps its because years ago I scratched the faces of a few blades with it because I was too lazy to tape them up. (These were nice custom blades.)

Mostly it serves as a fall back / fail safe position...in that in the back of my mind I know it's there if I either have difficulty with, or screw up one of the knives freehand, or have a blade that requires putting on a bevel and edge from the get-go because it didn't come from the maker properly done. At least I know that I have a way of making it come out pretty symmetrical.

Bottom line, though, is that I'm probably a poor person to ask. It's just my nature to gravitate to the simpler, less fussy, and more direct methods. Maybe I'm descended from William of Occam (Ockham) or something...or just a Luddite.

I feel the same way about the setup I made. It does everything I need it to do, and allows for a lot of control, esp on DLC coated blades and such where I want to lower the angle as much as possible without digging into the plunge line.

I still prefer to freehand, and unless I have a lot of work I still prefer to just freehand it. The outcome is virtually identical.

- Joined

- Oct 2, 1998

- Messages

- 47,374

I feel the same way about the setup I made. It does everything I need it to do, and allows for a lot of control, esp on DLC coated blades and such where I want to lower the angle as much as possible without digging into the plunge line.

I still prefer to freehand, and unless I have a lot of work I still prefer to just freehand it. The outcome is virtually identical.

Good to know I'm in excellent company.

The difference is probably that your freehand exceeds my freehand. I tend to be a "good enough" kind of guy, and don't mind sweeping some dust under the carpet. Though I can be meticulous on occasions when I feel the knife warrants it.

- Joined

- Jun 4, 2010

- Messages

- 6,642

Good to know I'm in excellent company.

The difference is probably that your freehand exceeds my freehand. I tend to be a "good enough" kind of guy, and don't mind sweeping some dust under the carpet. Though I can be meticulous on occasions when I feel the knife warrants it.

I tend to get a little more rock on the belly unless I really get in a zone, tho have been slowly improving consistency even there.

I learn a lot going back and forth guided to freehand, least of which is that it doesn't take much work to true up a freehand edge on the guide.

On warped knives one is much better off freehand, and a lot of knives have warps...

..

- Joined

- Nov 11, 2020

- Messages

- 23

Thanks for this. I'm new here and pretty new to knives in general, and have been planning to get some sort of sharpening system for Christmas. The Sharpmaker has been at the top of my list until I saw this new one from Worksharp last week. But after reading this, I think I'll probably stick with the Sharpmaker.

- Joined

- Oct 2, 1998

- Messages

- 47,374

Thanks for this. I'm new here and pretty new to knives in general, and have been planning to get some sort of sharpening system for Christmas. The Sharpmaker has been at the top of my list until I saw this new one from Worksharp last week. But after reading this, I think I'll probably stick with the Sharpmaker.

The Sharpmaker is very simple and versatile, as long as you understand its strengths and weaknesses. It's a wonderful tool for the things it does well.

- Joined

- Jan 4, 2016

- Messages

- 281

I have received my unit - all three stones are glued to the holder. I don't understand how customers are supposed to replace a stone.You have to slide the whole sharpening block off the steel rod, then you can pop the stones out of that block and replace them individually.

- Joined

- Jan 4, 2016

- Messages

- 281

As individual stones are glued, I don't see other options but to use a separate stone holder.

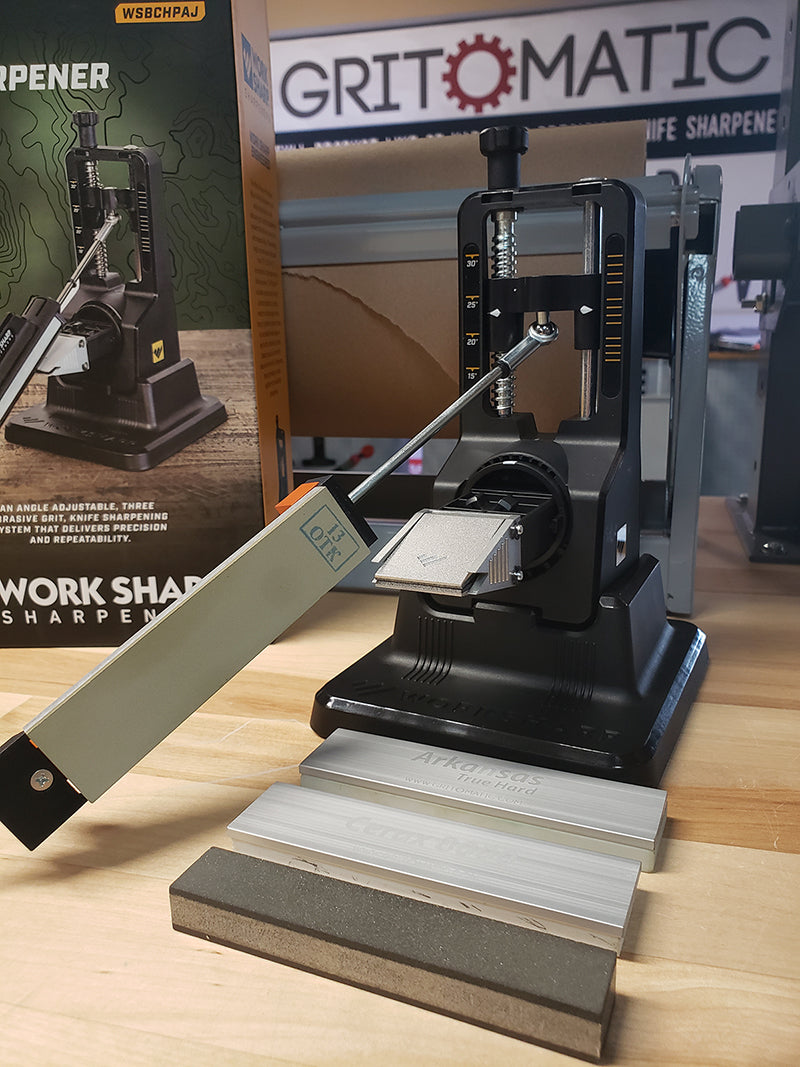

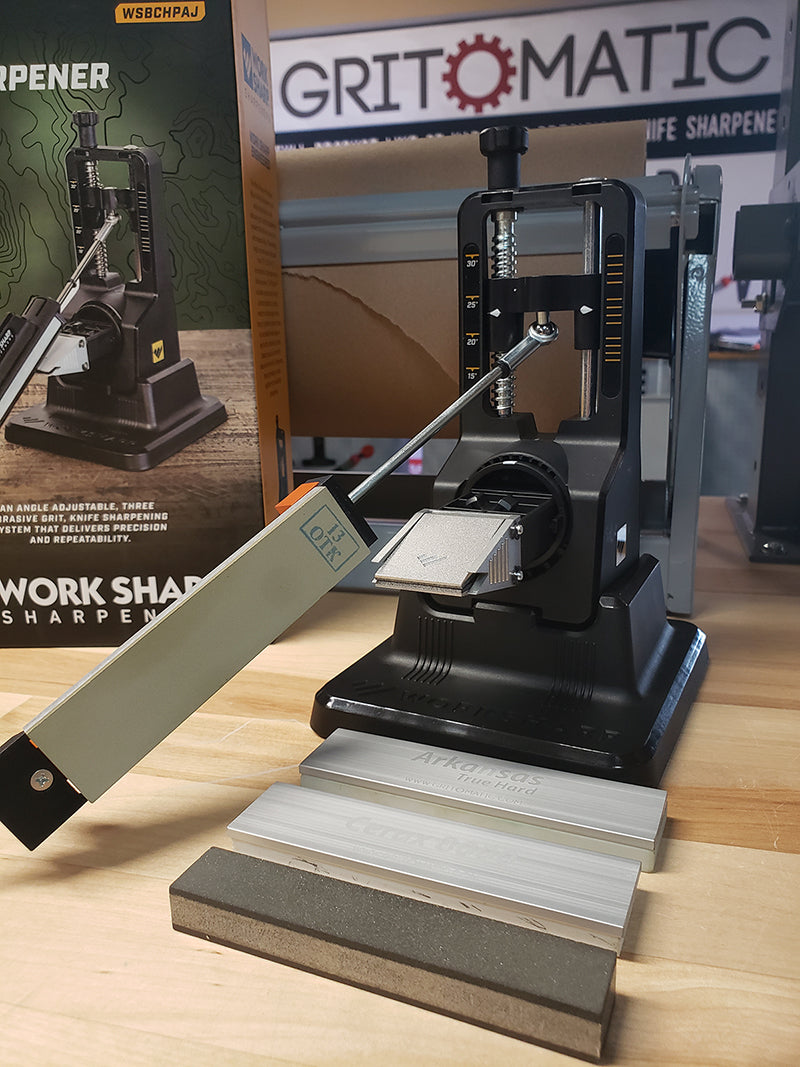

It's a prototype. Perfect for KME stones. 6" stones - pretty bad, not enough space for movement.

It's a prototype. Perfect for KME stones. 6" stones - pretty bad, not enough space for movement.

- Joined

- Oct 11, 2014

- Messages

- 1,040

While typing below, Konstantin's pic and comments helped. Glue must be designed to be easily broken, or stone has keyed plastic somehow?

BTW, Gritiomatic's KME stone carrier works on KME axe sharpener bringing EdgePro form factor length to KME axe sharpener!

In light of observations from you guys, I'm left scratching my head... . From 18:10 to :25 Worksharp says "individually replaceable", and shows disassembly, but only down to 3 stones in one plastic carrier, not individually.

. From 18:10 to :25 Worksharp says "individually replaceable", and shows disassembly, but only down to 3 stones in one plastic carrier, not individually.

BTW, Gritiomatic's KME stone carrier works on KME axe sharpener bringing EdgePro form factor length to KME axe sharpener!

In light of observations from you guys, I'm left scratching my head...

- Joined

- Jan 4, 2016

- Messages

- 281

When I try to take the diamond with a knife, it starts bending. 1.5mm thick ceramic stone will immediately break. I misunderstand something...

- Joined

- Sep 23, 2014

- Messages

- 1,287

Hmm,When I try to take the diamond with a knife, it starts bending. 1.5mm thick ceramic stone will immediately break. I misunderstand something...Tri-brasive™

on the other Tri-brasive™ the plates/stones seem to slide out

Last edited:

- Joined

- Sep 23, 2014

- Messages

- 1,287

Hmm,When I try to take the diamond with a knife, it starts bending. 1.5mm thick ceramic stone will immediately break. I misunderstand something...Tri-brasive™

on the other Tri-brasive™ the plates/stones seem to slide out

Last edited:

- Joined

- Sep 23, 2014

- Messages

- 1,287

Hi,^Yup. They're cheap!But if you wanna put anything less than a 15 dps edge on these guys, or any similarly shaped paring knife, the Worksharp sharpener here can't help you. Freehand it is.

Can you do this trick with it?

Wowbagger I sharpen small slip joints on my KME often with great results. I simply put some masking tape on the scales and clamp down on them in the standard KME jaws because I'm too cheap to buy the penknife jaws. It's a little trick I picked up on Youtube.

soc_monki

Gold Member

- Joined

- Apr 5, 2019

- Messages

- 1,888

I thought about getting one to try it out and compare it to my old Lansky. I like the clamp and how it basically auto-positions the spine of the knife for you. I love how simple the design is and the ease of use. But I don't think I can bring myself to order one because I can so easily and quickly sharpen/touch up or reprofile knives on my stones. And I'm not limited by blade sizes (couldn't do my BK7 on a Lansky or this Worksharp, at least not easily!), or angles (I don't even pay attention now, I either light the angles I have or I reprofile to a lower angle...). I may use an angle guide to start out, like I did reprofiling my XM-18, but after getting the initial ballpark of the angle I want, I just get to it.

Sure, I convex my edges because I go back and forth rather than just edge leading or trailing, and my edges may not be perfect in appearance or angle, but if its sharp and cuts well that's all that matters. I also sharpen with my stones in hand, and it works for me. So I may pick one of these up later to try it out, but I've been perfectly happy freehanding. It took me a little while to find some techniques that work for me, but now that I have I find it hard to try and go back to a clamp system. Still have my sharpmaker, and will always have it, it's just awesome for touch ups and serrated edges, but I don't really own any any serrated pocket knives. Need to change that and get a serrated Shaman or something...

Sure, I convex my edges because I go back and forth rather than just edge leading or trailing, and my edges may not be perfect in appearance or angle, but if its sharp and cuts well that's all that matters. I also sharpen with my stones in hand, and it works for me. So I may pick one of these up later to try it out, but I've been perfectly happy freehanding. It took me a little while to find some techniques that work for me, but now that I have I find it hard to try and go back to a clamp system. Still have my sharpmaker, and will always have it, it's just awesome for touch ups and serrated edges, but I don't really own any any serrated pocket knives. Need to change that and get a serrated Shaman or something...

Hi,

Can you do this trick with it?

Would test if I could, but I returned mine. Overall this thing wasn't bad, it did a pretty good job on the Spyderco I demo'd. I think it is a pretty good option for getting typical folders, and medium to large kitchen knives, hair-popping sharp without a huge effort. But I was not happy with the limitations on the clamp, those are some serious limitations. Sent feedback to both Amazon and Worksharp that they need to update the descriptions as I think consumers will get frustrated when they find out this cannot sharpen a lot of their knives to a reasonably acute angle. For example, if I bought this and was depending on it to be a general knife sharpener, I'd be really frustrated to learn things after the fact such as that I couldn't sharpen any of my kitchen paring knives to 15 dps, or that FFG blades aren't gripped as well by the clamp and tend to wiggle around. Also the limitations of the tiny sharpening block and stones. It's ok, but not great, and definitely you can do more with Sharpmaker as you can sharpen all types of knives, have more sharpening media to choose from, and can sharpen all your knives down to 15 dps.

I'm sticking with freehanding and Sharpmaker. If I ever feel the urge to upgrade to one of these guided rotating-arm type sharpeners, the one that IMHO looks most interesting in design, good clamping ability, and stone options, is Hapstone R2.

Jacques Mi

Gold Member

- Joined

- Jan 27, 2021

- Messages

- 1,367

I ordered this yesterday but I'm not sure if this was a good idea since I mostly carry and use traditional slip joint folders. How will this sharpener perform on them? Any info or pics will be greatly appreciated.

777 Edge

Dealer / Materials Provider

- Joined

- Sep 16, 2019

- Messages

- 1,204

I'm working on 3D printable upgrade designs for the Precision Adjust. Once done, I'm planning on making them available free like my other designs and upgrades.

I'm already testing a very good candidate for an upgraded clamp - the very affordable KakBritva aluminum clamps. I'm designing a 3D printable clamp bar with magnetic mount to change out with the original Precision Adjust clamp.

You simply screw the aluminum KakBritva clamps onto it, position them where you want them and swap my magnetic mount bar out with the original Precision adjust magnetic clamp unit. Easy as that.

This will likely allow sharpening angles down to about 13 degrees per side for a blade the size of a Victorinox main blade.

I'm also working on upgrades to be able to use a standard 6mm sharpening rod with printable clamps so you can easily use most edge pro type stones with it.

Those interested, let me know.

Stand by for updates if there is enough interest...

I'm already testing a very good candidate for an upgraded clamp - the very affordable KakBritva aluminum clamps. I'm designing a 3D printable clamp bar with magnetic mount to change out with the original Precision Adjust clamp.

You simply screw the aluminum KakBritva clamps onto it, position them where you want them and swap my magnetic mount bar out with the original Precision adjust magnetic clamp unit. Easy as that.

This will likely allow sharpening angles down to about 13 degrees per side for a blade the size of a Victorinox main blade.

I'm also working on upgrades to be able to use a standard 6mm sharpening rod with printable clamps so you can easily use most edge pro type stones with it.

Those interested, let me know.

Stand by for updates if there is enough interest...

- Joined

- Jun 25, 2021

- Messages

- 1

Very interested, I've already printed this lapping film holder and it works great. I did modify the plates that hold the film to be .5mm thicker so I could flatten them on a mirror with some fine grit sandpaper. I've been able to get some near mirror finishes with this system and the psa lapping films down to .3 microns.I'm working on 3D printable upgrade designs for the Precision Adjust. Once done, I'm planning on making them available free like my other designs and upgrades.

I'm already testing a very good candidate for an upgraded clamp - the very affordable KakBritva aluminum clamps. I'm designing a 3D printable clamp bar with magnetic mount to change out with the original Precision Adjust clamp.

You simply screw the aluminum KakBritva clamps onto it, position them where you want them and swap my magnetic mount bar out with the original Precision adjust magnetic clamp unit. Easy as that.

This will likely allow sharpening angles down to about 13 degrees per side for a blade the size of a Victorinox main blade.

I'm also working on upgrades to be able to use a standard 6mm sharpening rod with printable clamps so you can easily use most edge pro type stones with it.

Those interested, let me know.

Stand by for updates if there is enough interest...

https://www.thingiverse.com/thing:4856320