coolhand68

Gold Member

- Joined

- Mar 12, 2006

- Messages

- 1,373

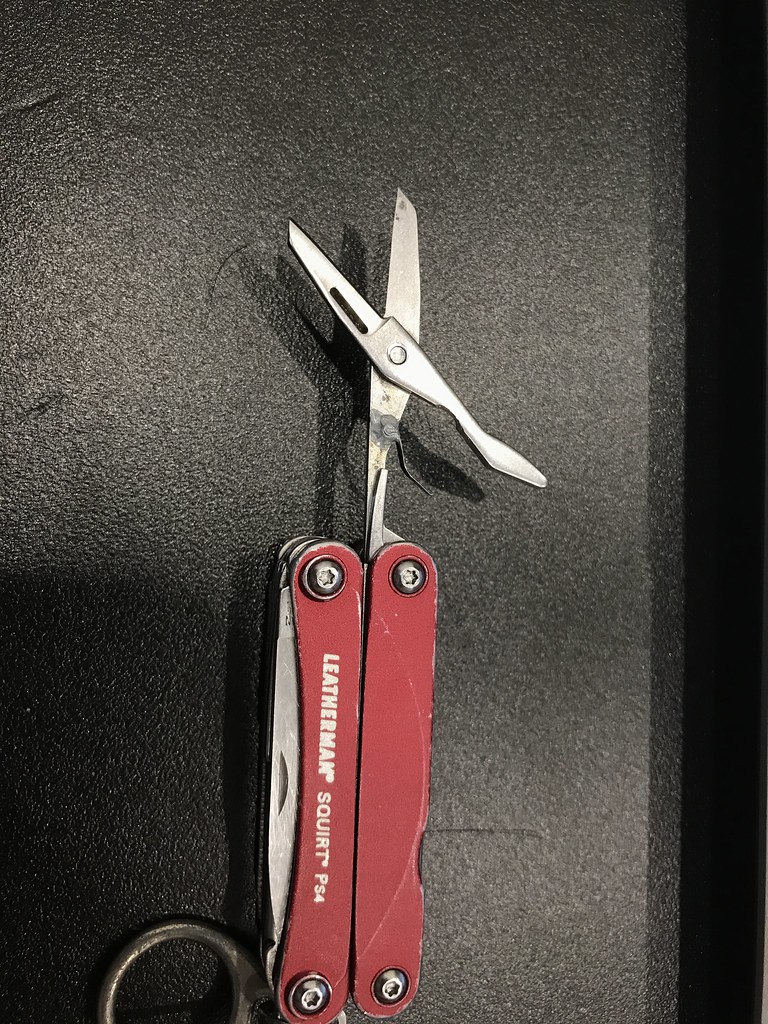

My guess is that their small tool lines likely end up needing warranty work more than the full size tools. This cuts into profits and eats up time. The accountants probably crunched the numbers and recommended they discontinue models that get returned for repair most often.