- Joined

- Jul 25, 2017

- Messages

- 2,462

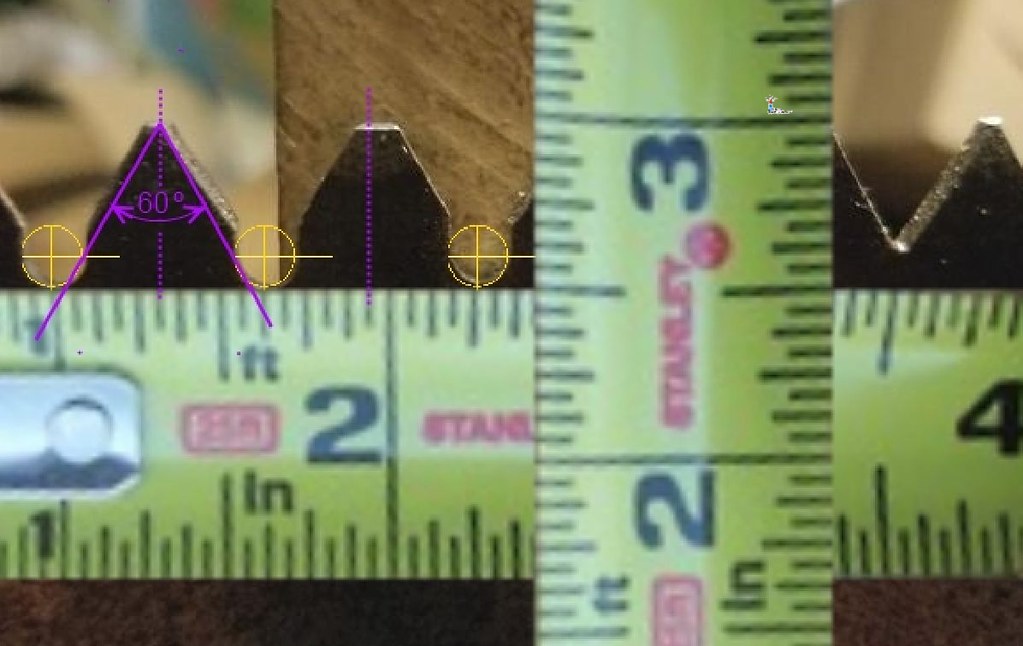

If you look at the tooth closest to the heel of that 48" Disston, you will see what the original tooth profile looked like. Most casual filers will not reprofile when sharpening their saws, as it's time consuming. But by not doing that, the teeth will become squatty. I'm guessing you could put a chainsaw file in the U between the two heel teeth, but that separation was absent from most of the others when you first started. The last plain tooth saw I filed, I cut all teeth to the same length and shape and used a round file to establish the bottom depth between the teeth. I also ran a wood screw into a small block of wood to use as a depth gauge to keep them all consistent.

Thank you trailtime!

The chainsaw file is something I want to do in the gullets I just did not know if that was the right thing to do. I would definetly like to make the teeth as uniform in height and profile as possible.

Would you be able to describe more what you mean and how you use the wood screw in the block as a depth gauge?

Thank you!

I anticipate some available saw time tomorrow