- Joined

- Oct 19, 2005

- Messages

- 19,687

I think its the thinner steel. I really like this tickness. And you nailed the Elf. Never felt so nimble a knife. Cool. What did you think of the pricepoint of the Trailmaster?

I think the Trailmaster provides a lot of value for the price. I could easily see folks wanting multiples - one to keep in the car, one in the bug out bag, another for general use, and so on.What did you think of the pricepoint of the Trailmaster?

What did you think of the pricepoint of the Trailmaster?

I'm not that skilled with the belt sander. It probably would have turned out better if I had hand sanded all the edges. It's really not difficult at all;

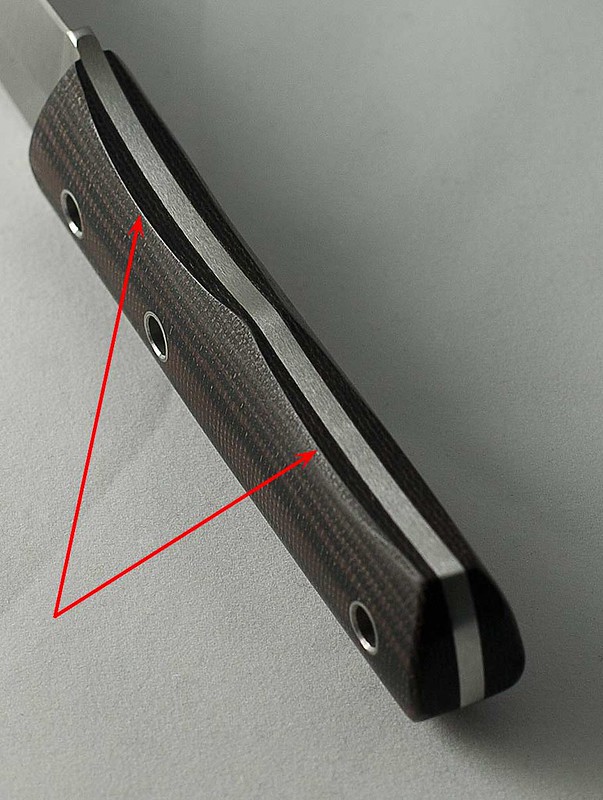

Thanks for the details on this, Robbie! I’ll be attempting a similar *carry melt* on my Utility later to soften some of the sharp edges. Will probably start with 800 or 1000 grit because it doesn’t need much, and I’d rather be too conservative then too aggressive. Will also post some first impressions.I don't think I can capture that very well in a photo, but below is my best attempt. The very bottom of the scales are ground flat with the tang. The side is curved, and where those two meet (identified by the arrows in this photo) had a slight edge. It was not as pronounced as the edge at the butt, and I wouldn't say it was really uncomfortable in the hand, but it was distracting. I suspect it would become more noticeable if using the knife for a long period of time. Yes, ministrations were effective. This photo is after the sanding; I didn't take a before picture.

I may have cheated a little. I have an entry level 1 x 42 inch belt sander from Kalamazoo Industries, and used it to knock the edge off these scales. I didn't want to take much off, so I used a 1000 grit belt just on the butt's edges. I finished by briefly hand sanding with 1500 and then 2000 grit paper. I tend to use finer grain abrasives. I only hand sanded the underside, and the progression I used was 800 -> 1000 -> 1500 -> 2000. If I were to this again, I'd start with a coarser grit, probably 400. Again, I only wanted to remove a tiny bit of Micarta.

Great reviewLady1911 !!! From here on out, we will fix the sharp edges issue. I will look at the issue you mention around the pins too. Sounds like there is a small burr. Might be time to switch to micarta pins if we can't figure a cost effective way to remove the burrs. (IE, not adding a step)

Folks! Just as with Fiddleback Forge knives, we are DEPENDENT on your enthusiasm for your knives to sell Cumming Bladeworks knives. Please help us spread the word on this fledgling brand by posting your thoughts, pics, reviews, etc on other forums! We are working on getting patches for Cumming Bladeworks USA made. Once that happens, you'll be able to get one by sending Phillip a link to your posts at other spots about our new brand!

Great reviewLady1911 !!! From here on out, we will fix the sharp edges issue. I will look at the issue you mention around the pins too. Sounds like there is a small burr. Might be time to switch to micarta pins if we can't figure a cost effective way to remove the burrs. (IE, not adding a step)

It may have already been posted, but will you have some of the line @ Trackrock? Just haven't been able to keep up with everything since the initial announcement, freaking life getting in the way.

Looks great, and I love the orange!! Is it a Trail Master? Can I have it?imma try this again

good lord, the years of sanding have completely jack'd up my thumb muscles