This failure was intentional, not the fault of the knife. This was a cheap S1 that I broke to see how failure initiates in the blade. No great lessons here. Just FYI for people interested in this sort of thing.

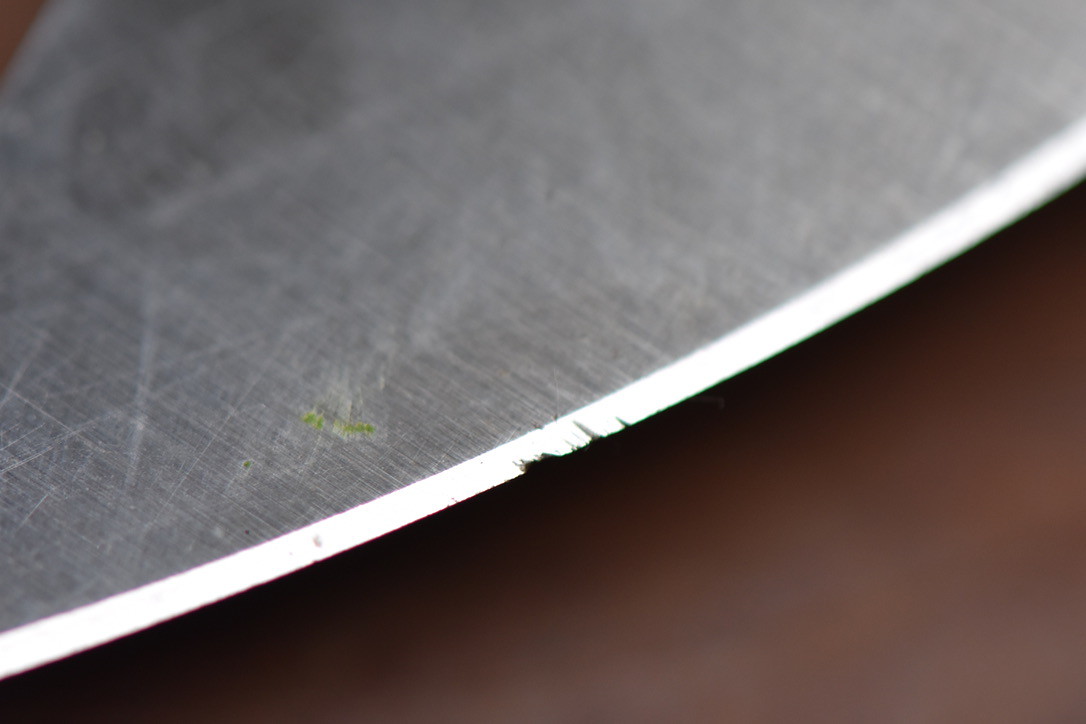

What happens is the knife delaminates with very little deformation prior to the break. This steel acted very brittle. I used a heavy vice and just hand pressure to break off a large chunk of the tip -- the first inch of the blade. Then I used a hammer for the thickest portion of the blade.

None of this would affect the knife when used as intended. This is not a slam on Fallkniven. I had no way to measure the force exerted. Both the hard VG 10 core and the softer 420-alloy cladding crack and break.

What happens is the knife delaminates with very little deformation prior to the break. This steel acted very brittle. I used a heavy vice and just hand pressure to break off a large chunk of the tip -- the first inch of the blade. Then I used a hammer for the thickest portion of the blade.

None of this would affect the knife when used as intended. This is not a slam on Fallkniven. I had no way to measure the force exerted. Both the hard VG 10 core and the softer 420-alloy cladding crack and break.

!

!