Every time I see this company (Dictator) mentioned, everyone's focusing about the copying designs thing. What I have NOT seen mentioned yet is if any one of the other companies has any sort of patens on any part/parts of this general design. If they don't, well, what do they expect? Basically, the one who makes it the best is going to win out.

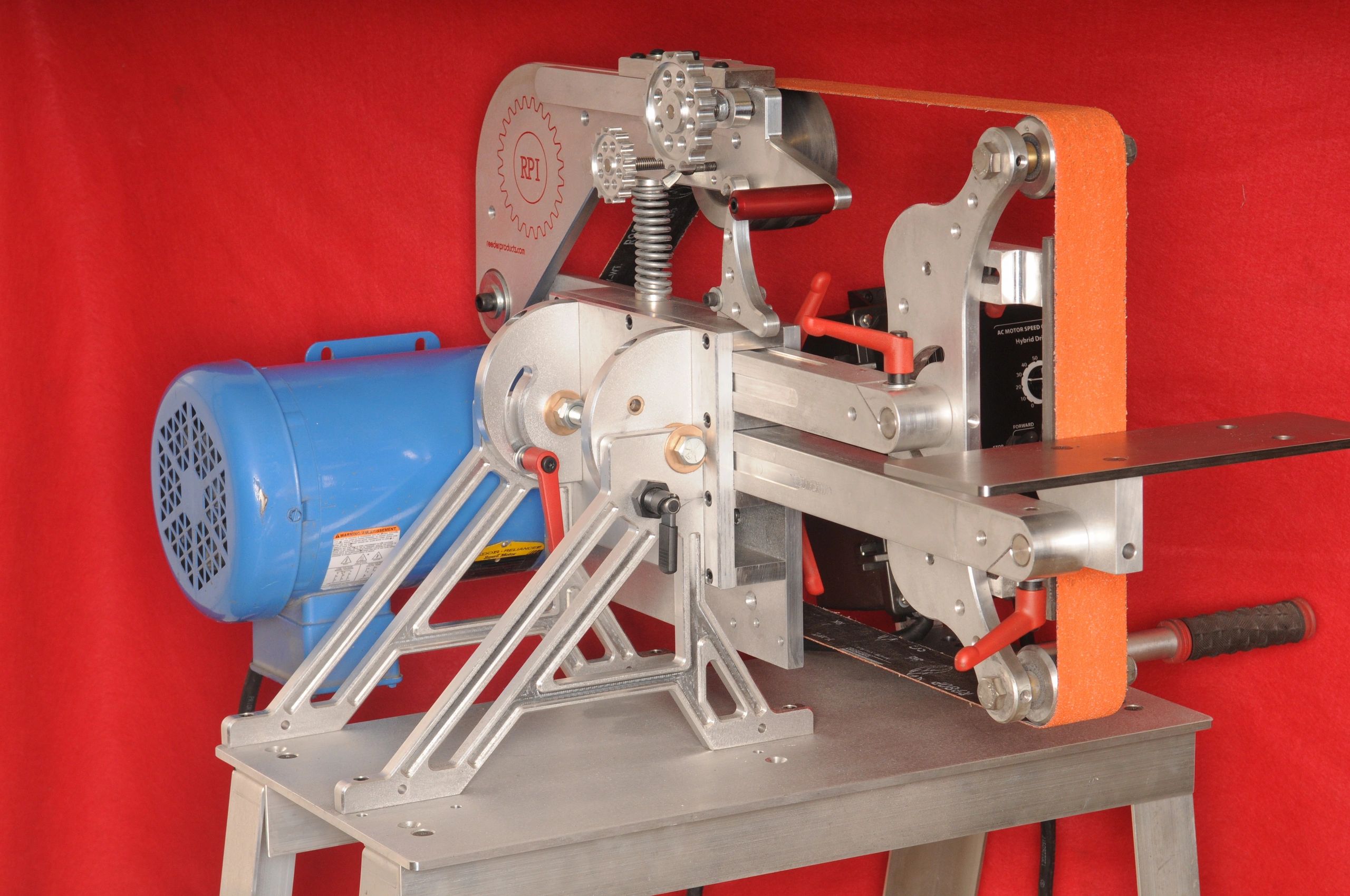

Having said that, I have recently bought one of their Bandit grinders. I'm sure I'll be able to sort it out....eventually. I'm currently trying to get a phone call with them to sort out the pulley alignment issues with it. It appears that there is no way to align them without modifying it somehow. And that means machining. Honestly, they are so close, but blew it on the small details, and if you read their literature, they go to great lengths to say how they do it best.

I'll tell you right now, if you want a good result, you better have facilities/skills to drill, mill, tap, weld, grind, problem solve, re-engineer, and some sort of painting.