- Joined

- Nov 15, 2005

- Messages

- 1,205

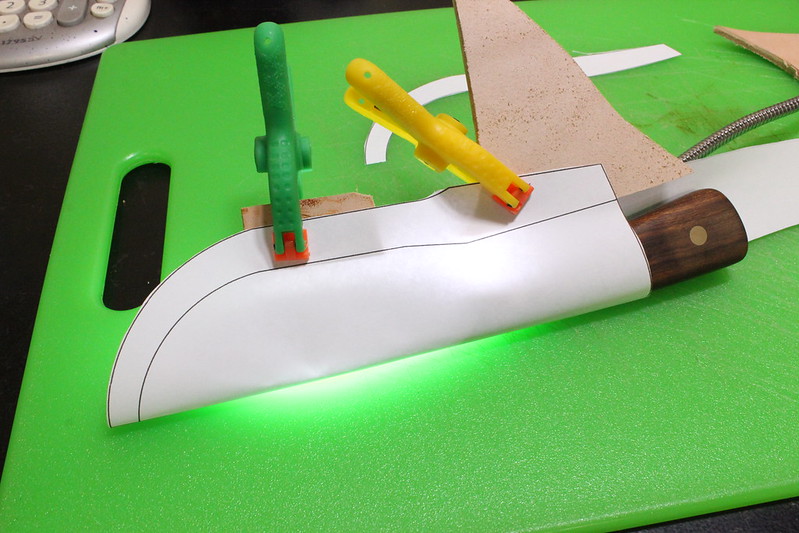

So I'm planning on crafting a leather sheath for this knife!

Knife distentions (PDF) here: https://www.dropbox.com/s/xxf2gyypusejfeo/JKeeton - Skinner.pdf?dl=0

I was wondering if you pouch sheath makers have some rules of thumb for things like:

JKeeton

PS: If the answer is: Try it out then adjust the next one... that's fine; I'm just looking for the best possible starting point to reduce iterations!

This is the design I currently have speced out.

Whole Layout:

Handle Section:

Belt Loop Section

EDIT:

I meant to have this picture as well:

Knife distentions (PDF) here: https://www.dropbox.com/s/xxf2gyypusejfeo/JKeeton - Skinner.pdf?dl=0

I was wondering if you pouch sheath makers have some rules of thumb for things like:

- Distance between template edge and welt

- Welt retention section spacing from template

- Distance between template spine and center line

- Based off leather thickness for the fold?

- Pocket size for the handle

JKeeton

PS: If the answer is: Try it out then adjust the next one... that's fine; I'm just looking for the best possible starting point to reduce iterations!

This is the design I currently have speced out.

Whole Layout:

Handle Section:

Belt Loop Section

EDIT:

I meant to have this picture as well:

Last edited:

... I must of set it down on something dirty. I've tried to clean it off with Bick 5 without success...

... I must of set it down on something dirty. I've tried to clean it off with Bick 5 without success...

. You draw with pencils and I draw with CAD; same thing.

. You draw with pencils and I draw with CAD; same thing.