It used to look about like that one, LOL. He told his fairly recent employer that he'd only crashed a few times in about 3 years on the job. The shop guys didn't believe him. Then he told them about it and that when he does, he does it right.

He likes the new job and they love him.

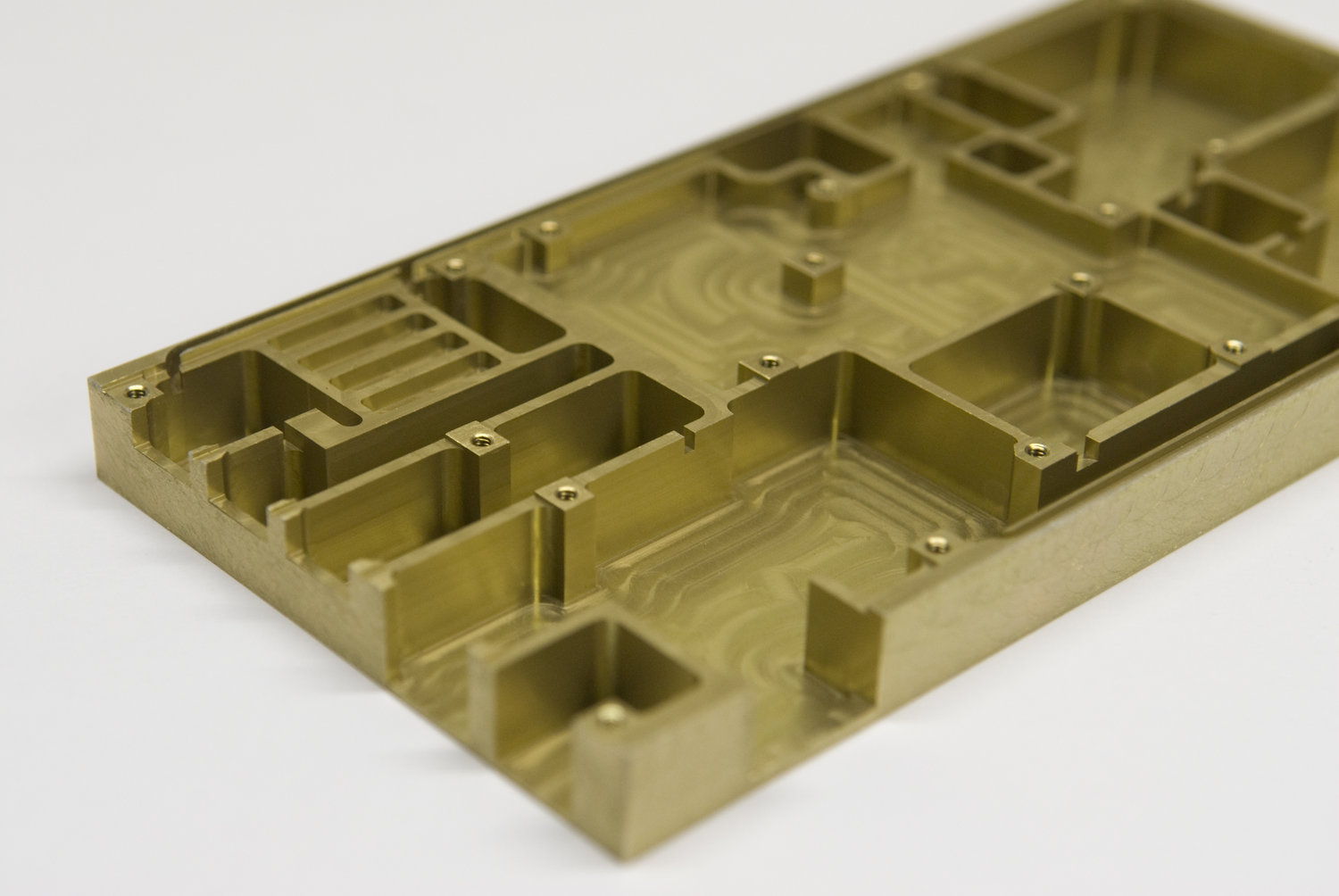

Oh, and he's big on the geometric tolerance stuff, speeds/feeds/DOC and all that. He saved them quite a number of hours on a run of parts when he first got there just by optimizing the cutting. Speed freak. He does a tiny bit of consulting for a satellite company on the side on how to best make parts and fixtures, for $65./hr. They have plenty of engineers to do math, but the boy knows how to whittle metal.