- Joined

- Jun 6, 2019

- Messages

- 388

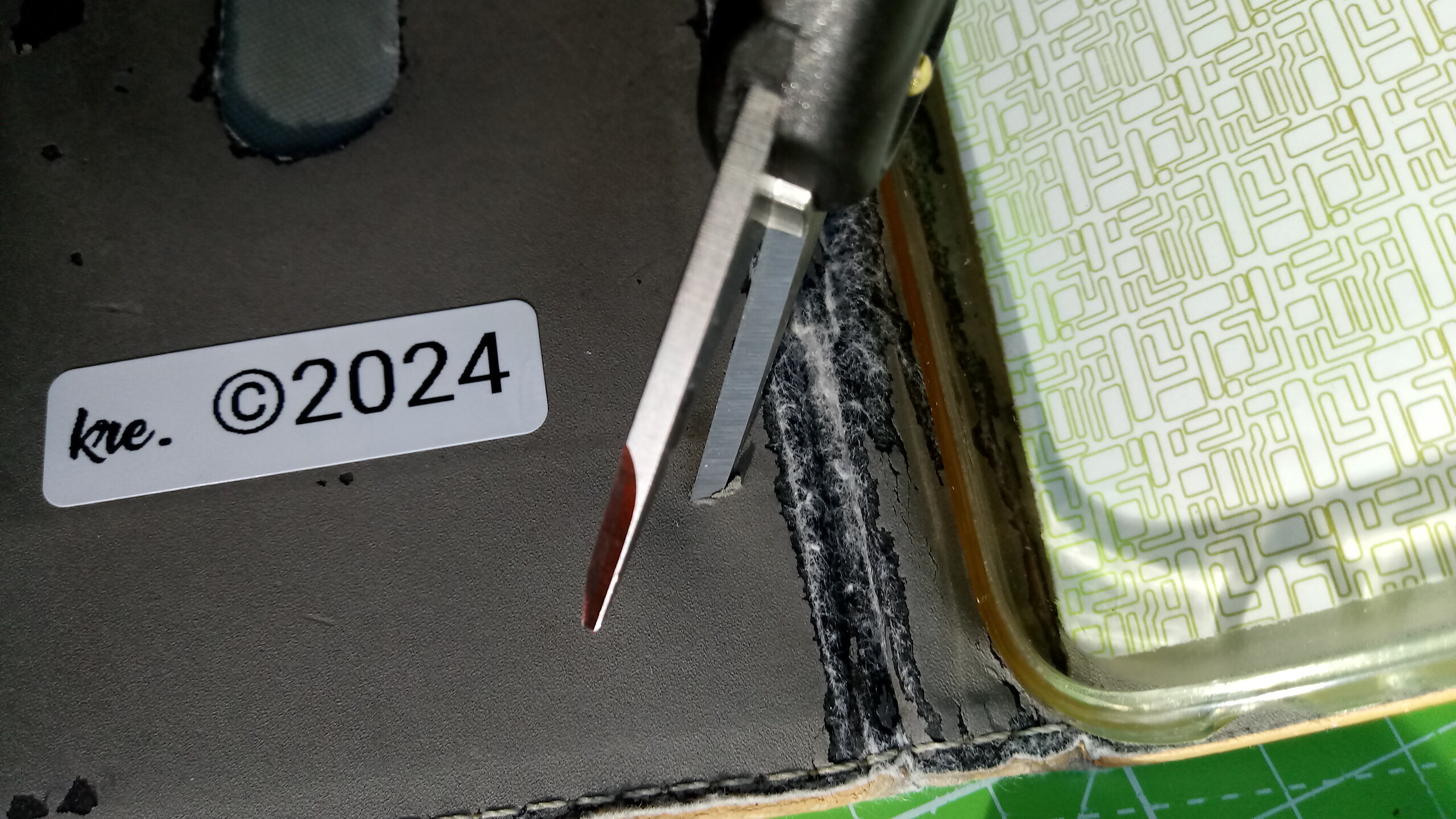

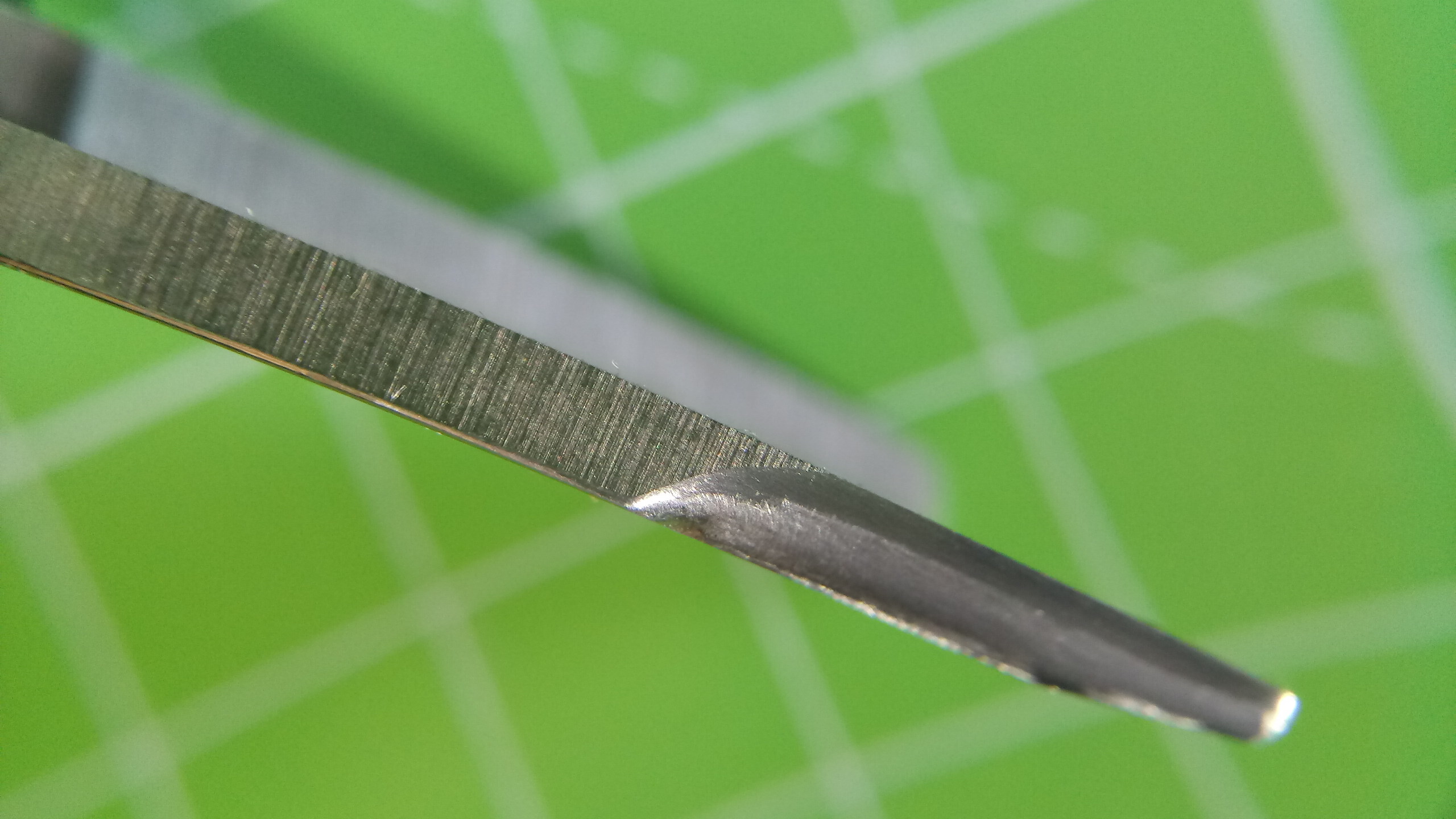

Yesterday... (I never seem to get around to posting the same day I sharpen.)... Anyway, yesterday was a small, 5" or so, kitchen chopper (santoku?) of Mrs. McGee's. As I recall, it was about $5 and boasted high carbon steel. I lowered the angle from 20* to 18*, so we'll see how that goes.