Internet sucked last night. Was off most the night.

But it did give me some time to play around with a new design.

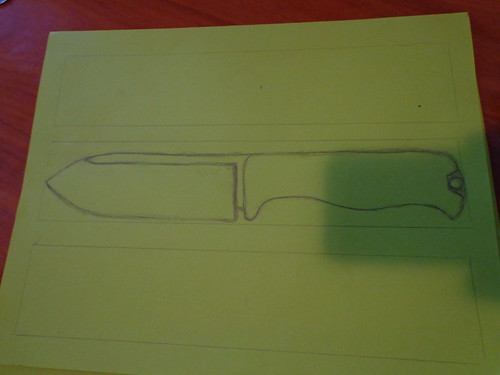

After drawing it all up it reminded me of 100 different knives.... So i decided to call it the "Average Woody" LMAO

.... Soon there will be a "Woody Pecker", an "Average Woody" A "Crooked Woody" with a slanted handle, And a "Big Wood"

Ya see where im going with this?? HAHA

Sorry for the crappy picture. Didnt feel like going down stairs and turning everything on quite yet.

Its a hair under 10" with a generous amount of handle.

The sharpening notch choil area will probably be difficult to get cleanly profiled out.... But i like it like that, so ill attempt it.

.... Soon there will be a "Woody Pecker", an "Average Woody" A "Crooked Woody" with a slanted handle, And a "Big Wood"

Ya see where im going with this?? HAHA